A bright future for 57-mm is envisioned in KB "Burevestnik" based at Nizhny Novgorod. While not exactly a breakthrough development, as it is essentially a shortened barrel of famous S-60 gun means it does not retain the brillliant ballistic qualities of its predecessor. Some suggest that it might be innovative in terms of feeding mechanism and seems the main R&D efforts are concetrated on getting bigger rate of fire and to speed-up changing ammo casettes while not overcrowding module and vehicle ammo station with highly explosive rounds.. The system is only slightly related to the 57-mm battle compartment tested for PT-76B in late 90-s. Other innovations must be in area of remotely controlled fuses of the projectiles, PGMs although I still expect better gun ballistics for naval version in the future as well as considerably higher rate of fire (similar to BAE Systems Mk 110 57 mm gun of the LCS).

The Navy version seems to be ready for tests.

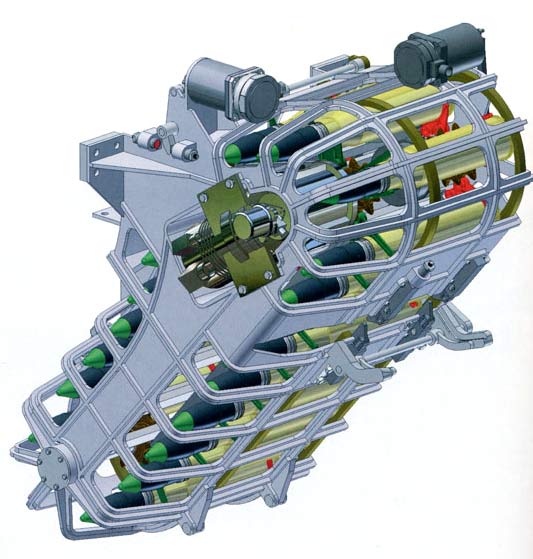

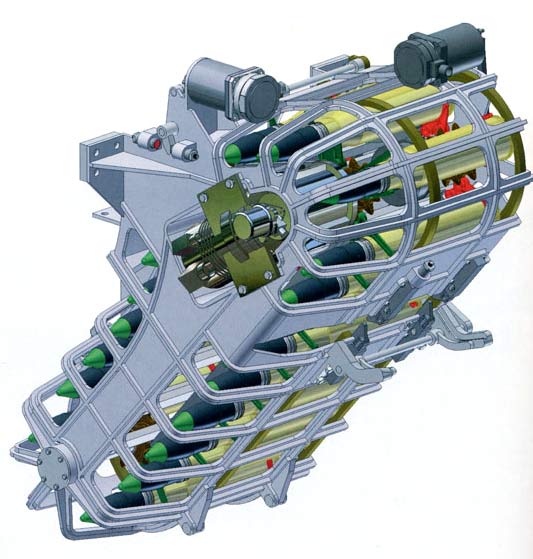

The feeding mechanism in its current stage consists of folllowing-

Automated ammo rack for 20rounds that are ready for immediate fire:

b)it is supplied with behind the turret mechanised storage for 100 rounds that reloads the rack in 10-15s. Additionaly you can choose which type of ammo to reload first in the rack.

Module is autonomus which means it may eventually be installed on the broad range of vehicles:

Some additional thoughts here(in Russian):

http://andrei-bt.livejournal.com/14202.html#cutid1

This is also interesting proposition - joint chassis E-300 not directly related to future platforms, but allows a commonality of T-72B, T-90 related vehicles to be sufficiently risen.

Here is babelfish translation of this article: http://otvaga2004.narod.ru/xlopotov_8/0rea_2009.htm

A real sensation of the Ural weapons Salon «RUSSIAN EXPO ARMS 2009" has become a new universal chassis from OAO Uraltransmash. The appearance of this machine are interested in many experts, although most of the media have not noticed it at all. In these days of the exhibition was working delegation of the Defense Ministry. Judging by how long the experts acquainted with the layout of a new unified chassis, this development deserves special attention.

"This layout was presented to the public for the first time. At the moment it is one of our major developments. This chassis to unify with the main battle tank Russian T-90 ", - said General Director of Uraltransmash" Yuri Comrat.

Manufacturer's designation of a new car - "E300". According to the deputy chief designer, head of SKB-Transmash special JSC Uraltransmash "Komarov, Vladimir Fedorovich, E300 - is their initiative only development. Action in all senses. Both on the idea and funding. Their appearance a new chassis immediately aroused great interest, both in military and military-industrial circles. "I just tell you my feelings, they can certainly not be true, but I have a feeling it happened that both the military and among the industrialists such an easy panic rose, because before a General Discussion, papers are different. Papers can be describing whatever you want them. And we have a really built machine that runs, you can touch, kick, next to another car place "- said in an interview with Vladimir Fedorovich. The reason for such "silent panic" is simple - the suspension and "BuK" and "Tunguska" exhausted themselves to the possibility of further growth of the load. The same situation with his family for "URALTRANSMASH" chassis ACS "Acacia" and "MSTA". There are always applied to support roller relatively small diameter and a small carrying capacity of the chassis, which in turn imposes limitations on the growth of the mass of vehicles and payloads, respectively. At the same time, the use of heavy armored vehicles as universal as inappropriate. This option is offered Nizhny Tagil UKBTM is justified to create a unified line on the chassis front edge of the combat vehicles - tanks, BMPT, TBTR, CBT, LMC, BREM, BIS, other heavy engineering vehicles and machinery support. However, the heavy tank chassis with protection level, and therefore the mass, it is absolutely not required for the SAU, SAM and the various crank, radar installations. World trends at the same time require unification of all park military vehicles. How to reconcile these contradictions? Exit Ural Designer found in the application of a single unified platform.

As conceived by Chief Designer - CSC chief Valery Alexandrovich and lead engineer on the car Dmitry Malyshev (can not but rejoice that the engineering staff, we started getting younger - Dimitri just 26 years) using a light body chassis on a single, unified platform with tanks having a high bearing characteristics, makes it possible to carry up to 25-28 tons of payload at a total machine weight to 50 tons.

To compare:

weapon «BUK-М1

chassis GM-596

chassis weight, kg 24000

total weight, kg 35500

maximum cargo load, kg 11500

weapon «Tunguska-М1»

chassis GM-5975

chassis weight, kg 23800

total weight, kg 36000

maximum cargo load, kg 11500

weapon «TOR-М1»

chassis GM-5955

chassis weight, kg 27000

total weight, kg 37000

maximum cargo load, kg 11500

chassis «future E-300»

chassis weight, kg 24500

total weight, kg 50000

maximum cargo load, kg 28000

That's why as a basic machine for the platform has been selected T-90S tanks. Of course, depending on the type and type of loading body will change. Simply by virtue of the functional features of the set of possible states of load it can not be the same, but the body after all - it's not a problem! The main thing - it is a platform. Decision must be made that suspension will be precisely this. It can serve as a basis not only for the installation of 155-mm long-range howitzer M-388 (developer of "plant number 9), but also for other military vehicles. Such as the control point air defense radars, launchers of anti-aircraft missiles, tracked mine layers, and others. However, in the case of ACS, it is not applicable tank blade dampers. For ACS and SAM launchers, they must be controlled and at least dual-mode. For this reason, blade dampers T-90 tank have been replaced by telescopic. Another technical problem transmashevtsam ahead in adapting his chassis under the Buk. There probably need to introduce some additional control system, because "beech" in certain modes need a rigid fixation of the case. This matter is currently in the study.

MTO E300 chassis is identical MTO MBT T-90A, and depending on the expected loads can be accomplished with a front or rear. Tysyachesilny turbocharged four-stroke diesel engine V-92S2 production CTZ provides a new chassis power density from 20 to 35 hp / ton, depending on the final weight machines, and accelerates it to 65 km / h.

Transmission and automatic gear shift is also borrowed from the T-90A. Ease of management in addition to automatic transmission is the wheel. As explained by VF Komarov: "With the wheel, we just serve an administration-speed manual transmission, but it is very reliable!" Certainly the use of a manual transmission, OPF unlike locus and GOPA may seem modern and obsolete solution. But do not forget that the Russian military machine is distinguished from competitors in the first place great reliability and maintainability. In some cases a conservative approach to design gives the best results. As a good example in this regard it is worth recalling the history of the introduction of automatic GMT ESM-350m production SESM - French subsidiary of German company RENK on the Polish Tank PT-91M. It is because of problems with this transmission and logistics in general, the performance of the contract for the supply of these machines, Malaysia dragged on for 1,5 years and is in jeopardy. Moreover, the parameters of the reliability of logistics, these machines, according to Russian GOST simply would not survive the trials and were found to be unfit for use. But ESM-350m - is RENK! The world simply does not have a single manufacturer who could compete on equal terms with RENKom in this area. Of Russian industry in its present stage of development is better just hush up. In Russia, only one or two companies in a position to exercise that precision is required in the manufacture of GMT. Oils and other fluids have such a quality that, as encapsulated in the hydraulic system without prior training very quickly clog filters, and then everything just dies. Hydraulic leak due to one or other reasons is not only dangerous for the mobility, and catastrophic. But we are talking primarily about fighting machine that will most likely be exposed to enemy fire. And finally, it is worth recalling the low efficiency of GMT, the natural effect of the very principles of its work. Ukrainian KMDB developed and is now heavily advertised hydraulic transmission GOP-900 is designed for use in hydro-mechanical transmissions of heavy tracked vehicles weighing up to 60 tons of supposedly unbeatable efficiency. Perhaps this is so. However, its level of industrial development and implementation is at the level close to zero values. That's when Ukraine will be able to make this the GOP on an industrial scale and sells it to the mass production of combat vehicles, it is only in this case, you should pay attention to their advertising promises. Another important factor is also the cost of GMT. For example, the cost of the same ESM-350m exceed the total cost of some variants of the modernization package offered UKBTM for the T-72M1. A further drag on the issues of operation and repair: neither Russia nor the country - the traditional buyers of our defense products (Middle East, North Africa and Asia) do not have databases for quality repair and maintenance of such things.

The ideology of the creation of combat vehicles Ural designers can not use raw, unreliable and untreated solutions. GMT, the GOP - it is certainly beautiful, it's certainly advanced technical solutions, but again, underneath all this must be a genuine production base!

At the same time, however, as opposed to a healthy conservatism in the transmission of the chassis E300 is equipped with the latest set of digital avionics production Chelyabinsk "Electric." Thanks to digital technology reduced the number of control units and inter-block connections, resulting in the mass of the cable bundle has been cut 15 times. The driver has at his disposal zhidkokrstallichesky display, compact and convenient control panel, implemented the mapping information on an additional panel placed in the middle of steering column controls. Jobs of the crew on this prototype equipped with standard seating, but on request, they can easily be replaced with chairs extra comfort. Provides the installation of the equipment for air conditioning and maintenance of the microclimate, as the placement of the crew and for cooling electronic equipment.

According to experts, the use of a single platform to optimize production, introduce a system of integrated services, service and repair. Correctness of embedded designers Ural ideas at this time is confirmed in practice - on the Indian armed forces defense now goes SAM «Akash» which as a platform base chassis used T-72 tank. This platform in a complex «Akash» a launcher, machine control panels and radar with phased array. Interestingly, the original designs of the Indian developers of this complex, as a base was to be used BMP chassis, but it is having low bearing capacity could not bear the load and the base of the T-72 has fallen here just in time. Given the massive rearmament of Indian Army on the MBT T-90S, suggestions uraltransmashevtsev on his new chassis more than appropriate. E300 chassis paves the way to the region and Russia's new self-propelled guns and SAM. Unfortunately, if in terms of design and technological solutions to problems at the moment are not available, in terms of further technical policy of the ROC and the prospects of procurement issues have mass. This clash of interests between industrial groups, personal ambition, but mainly all depends on the reluctance of high rank ordering departments to take responsibility. Exactly the same thing, but in terms of prospects for tank development and expressed the new CEO of OAO Scientific Production Corporation Uralvagonzavod Oleg Sienko: "There are people who do not want to take responsibility!". However, we hope that the state's interests outweigh the petty squabbles and tip the scales in the right direction.