+71

xeno

ludovicense

Sprut-B

Podlodka77

Krepost

Belisarius

Rodion_Romanovic

wilhelm

Robert.V

Dr.Snufflebug

caveat emptor

Broski

Gazputin

thegopnik

andalusia

Lennox

Daniel_Admassu

Mir

ALAMO

limb

Russian_Patriot_

lancelot

Backman

Kiko

LMFS

Scorpius

PhSt

dino00

marat

miketheterrible

Dima

Hole

PapaDragon

KiloGolf

Singular_Transform

JohninMK

Singular_trafo

Zivo

william.boutros

Book.

KoTeMoRe

Project Canada

Rmf

mutantsushi

Prince Darling

Svyatoslavich

higurashihougi

eehnie

Neutrality

macedonian

George1

flamming_python

Vann7

AbsoluteZero

kvs

GarryB

Werewolf

Mike E

sepheronx

KomissarBojanchev

Firebird

magnumcromagnon

gaurav

TheArmenian

AlfaT8

Viktor

Regular

Cyberspec

TR1

Austin

Sujoy

75 posters

Russian Auto Industry

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°501

Re: Russian Auto Industry

Re: Russian Auto Industry

Dima, kvs, PapaDragon and Hole like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°502

Re: Russian Auto Industry

Re: Russian Auto Industry

flamming_python, kvs, PapaDragon and Hole like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°503

Re: Russian Auto Industry

Re: Russian Auto Industry

flamming_python likes this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°504

Re: Russian Auto Industry

Re: Russian Auto Industry

kvs, Hole and Daniel_Admassu like this post

Daniel_Admassu- Posts : 149

Points : 151

Join date : 2020-11-18

Age : 44

Location : Addis Ababa, Ethiopia

- Post n°505

Re: Russian Auto Industry

Re: Russian Auto Industry

The Belarusians seem to be doing well in terms of design. It is sad EU sanctioned MAZ a while ago. Is its primary market in Russia or Europe?

kvs- Posts : 15873

Points : 16008

Join date : 2014-09-11

Location : Turdope's Kanada

- Post n°506

Re: Russian Auto Industry

Re: Russian Auto Industry

Daniel_Admassu wrote:The Belarusians seem to be doing well in terms of design. It is sad EU sanctioned MAZ a while ago. Is its primary market in Russia or Europe?

Not the EU. The market is mostly outside of NATzO.

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°507

Re: Russian Auto Industry

Re: Russian Auto Industry

Sorokin's Hydrogen: how GAZ sees the development of volatile gas technologies.

In one of the reviews of the Komtrans exhibition in Moscow, we talked about prototypes of promising hydrogen buses with fuel cells — over time they should replace the current electric buses. One of these machines was presented by the GAZ Group, but later its president Vadim Sorokin told about the prospects and alternative developments in the hydrogen field.

The main task of equipping electric vehicles with hydrogen installations is to increase the power reserve between recharges. And in theory, installing an electrochemical generator with fuel cells that recharges batteries on the go looks like a simple and attractive solution to this problem. But it is worth digging deeper — and the advantage of this technology is not so obvious anymore.

Its first disadvantage is a large chain of all systems and their complexity. We fill the hydrogen into the cylinders, it enters the fuel cells, which, in turn, recharge the battery, which feeds the electric motor with energy — and only it drives the wheels. Each of the links in this chain requires its own electronic control units, it is necessary to coordinate their work — and, of course, you need to carry all this with you, taking away space from passengers and cargo.

Of course, a vehicle with such a set of technological equipment costs a lot. How much? According to Sorokin, if an ordinary diesel city bus now costs about 12 million, and an electric bus based on it will cost about 36 million, then the cost of a similar water bus will easily exceed the mark of 100 million. If such a sum is feasible for a rich Moscow, then it is unlikely that they will even look at such expensive equipment in the regions. Moreover, if we imagine the future mass transition to fuel cells as a fait accompli — where to put large-scale production and developments in the field of conventional internal combustion engines and, for example, gearboxes? There is no answer to this question now.

That is why they are working on GAZ not only on their own fuel-element hydrogen bus, but also on traditional technology — when hydrogen, mixed with oxygen, is burned in a conventional piston engine. This idea is not new: at different times, manufacturers have already tried to build similar units, which, however, require special study. The heat of combustion of hydrogen is three times greater than that of gasoline, and this entails additional problems with detonation, and materials need more heat-resistant.

Not so long ago, we wrote that MAN is currently working on the creation of a "hydrogen internal combustion engine" — well, now GAZ will be her company. It is assumed that a bus with such an engine will be 2.5 times cheaper than a hydrogen bus with fuel cells and one and a half times cheaper than a traditional electric bus with batteries.

It is clear that creating such an engine is not an easy task. At the same KAMAZ, they are skeptical about the initiatives of their competitor — and they themselves are working on fuel cells. However, at the Comtrans exhibition, Sorokin said that the first experimental hydrogen engines should appear before the end of this year, and the calibrated unit in the bus will be presented in 2023.

Source:

In one of the reviews of the Komtrans exhibition in Moscow, we talked about prototypes of promising hydrogen buses with fuel cells — over time they should replace the current electric buses. One of these machines was presented by the GAZ Group, but later its president Vadim Sorokin told about the prospects and alternative developments in the hydrogen field.

The main task of equipping electric vehicles with hydrogen installations is to increase the power reserve between recharges. And in theory, installing an electrochemical generator with fuel cells that recharges batteries on the go looks like a simple and attractive solution to this problem. But it is worth digging deeper — and the advantage of this technology is not so obvious anymore.

Its first disadvantage is a large chain of all systems and their complexity. We fill the hydrogen into the cylinders, it enters the fuel cells, which, in turn, recharge the battery, which feeds the electric motor with energy — and only it drives the wheels. Each of the links in this chain requires its own electronic control units, it is necessary to coordinate their work — and, of course, you need to carry all this with you, taking away space from passengers and cargo.

Of course, a vehicle with such a set of technological equipment costs a lot. How much? According to Sorokin, if an ordinary diesel city bus now costs about 12 million, and an electric bus based on it will cost about 36 million, then the cost of a similar water bus will easily exceed the mark of 100 million. If such a sum is feasible for a rich Moscow, then it is unlikely that they will even look at such expensive equipment in the regions. Moreover, if we imagine the future mass transition to fuel cells as a fait accompli — where to put large-scale production and developments in the field of conventional internal combustion engines and, for example, gearboxes? There is no answer to this question now.

That is why they are working on GAZ not only on their own fuel-element hydrogen bus, but also on traditional technology — when hydrogen, mixed with oxygen, is burned in a conventional piston engine. This idea is not new: at different times, manufacturers have already tried to build similar units, which, however, require special study. The heat of combustion of hydrogen is three times greater than that of gasoline, and this entails additional problems with detonation, and materials need more heat-resistant.

Not so long ago, we wrote that MAN is currently working on the creation of a "hydrogen internal combustion engine" — well, now GAZ will be her company. It is assumed that a bus with such an engine will be 2.5 times cheaper than a hydrogen bus with fuel cells and one and a half times cheaper than a traditional electric bus with batteries.

It is clear that creating such an engine is not an easy task. At the same KAMAZ, they are skeptical about the initiatives of their competitor — and they themselves are working on fuel cells. However, at the Comtrans exhibition, Sorokin said that the first experimental hydrogen engines should appear before the end of this year, and the calibrated unit in the bus will be presented in 2023.

Source:

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°508

Re: Russian Auto Industry

Re: Russian Auto Industry

GarryB and kvs like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°509

Re: Russian Auto Industry

Re: Russian Auto Industry

kvs likes this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°510

Re: Russian Auto Industry

Re: Russian Auto Industry

More than 5,8 thousand ambulances and school buses will arrive in the Russian regions.

The Russian government has adopted an order according to which emergency medical vehicles and school buses will be delivered to the regions in 2021. All the equipment is highly localized and produced at the GAZ, PAZ and UAZ enterprises, the press service of the Ministry of Industry and Trade of the Russian Federation reports.

In total, 1624 ambulances of classes B and C, as well as 4187 school buses will be delivered to the Russian regions in 2021. From the reserve fund of the Russian government, 5.6 billion and 9.7 billion rubles are provided for this, respectively.

"The program of updating the fleet of ambulances and school buses is an effective measure both for the development of transport infrastructure in the regions and for supporting Russian car manufacturers. Ulyanovsk Automobile Plant has included the order of the Ministry of Industry and Trade in the production plan" – Adil Shirinov, General Director of UAZ, said.

Source:

The Russian government has adopted an order according to which emergency medical vehicles and school buses will be delivered to the regions in 2021. All the equipment is highly localized and produced at the GAZ, PAZ and UAZ enterprises, the press service of the Ministry of Industry and Trade of the Russian Federation reports.

In total, 1624 ambulances of classes B and C, as well as 4187 school buses will be delivered to the Russian regions in 2021. From the reserve fund of the Russian government, 5.6 billion and 9.7 billion rubles are provided for this, respectively.

"The program of updating the fleet of ambulances and school buses is an effective measure both for the development of transport infrastructure in the regions and for supporting Russian car manufacturers. Ulyanovsk Automobile Plant has included the order of the Ministry of Industry and Trade in the production plan" – Adil Shirinov, General Director of UAZ, said.

Source:

Last edited by Russian_Patriot_ on Wed Sep 22, 2021 6:40 pm; edited 1 time in total

markgreven, dino00, x_54_u43 and Hole like this post

Hole- Posts : 11130

Points : 11108

Join date : 2018-03-24

Age : 48

Location : Scholzistan

- Post n°512

Re: Russian Auto Industry

Re: Russian Auto Industry

Russian_Patriot_ wrote:More than 5,8 thousand ambulances and school buses will arrive in the Russian regions.

The Russian government has adopted an order according to which emergency medical vehicles and school buses will be delivered to the regions in 2021. All the equipment is highly localized and produced at the GAZ, PAZ and UAZ enterprises, the press service of the Ministry of Industry and Trade of the Russian Federation reports.

In total, 1624 ambulances of classes B and C, as well as 4187 school buses will be delivered to the Russian regions in 2021. From the reserve fund of the Russian government, 5.6 billion and 9.7 billion rubles are provided for this, respectively.

"The program of updating the fleet of ambulances and school buses is an effective measure both for the development of transport infrastructure in the regions and for supporting Russian car manufacturers. Ulyanovsk Automobile Plant has included the order of the Ministry of Industry and Trade in the production plan" – Adil Shirinov, General Director of UAZ, said.

Source:

I hope this time the regions will look after them.

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°513

Re: Russian Auto Industry

Re: Russian Auto Industry

GarryB and PapaDragon like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°514

Re: Russian Auto Industry

Re: Russian Auto Industry

Borisov: the industry will be able to replace most of the imported scarce automotive components.

The Russian industry will not be able to replace all the scarce automotive components due to a lack of competencies for some products, but most of them will be able to. This opinion was expressed to journalists by Deputy Prime Minister of the Russian Federation Yuri Borisov on the sidelines of the Tyumen Oil and Gas Forum.

"Will the Russian industry be able to replace it? Potentially, it will be able to. Not on the entire product line, because we do not have the production assets of the necessary technological capabilities for the production of, say, high-tech microcontrollers and processors. This is a fact" – Borisov said. At the same time, he clarified that some of the products are gradually being replaced. "We have the necessary assets, where very high technologies in the field of power electronics are not required. Of course, these substitutions actually occur. So there is potential, and our enterprises are increasing volumes in this area" – he said, adding that this is a gradual process, and it is impossible to reach the required level of production at the same time.

According to Borisov, the shortage of automotive components affected not only Avtovaz and Kamaz, but also the main manufacturer of final automotive electronics, Itelma.

"The shortage of necessary components is experienced not only by Russia, but also by almost the entire global automotive industry. This is due to understandable reasons: the presence of an energy crisis associated with the pandemic, a sharp drop in production volumes, including in the global automotive industry, which led to the lack of demand for the necessary amount of all automotive components. Today we are getting out of this crisis. It is almost impossible to increase it at the same time, to reach the necessary level of production, this is a gradual process, the production capabilities of the entire global microelectronics industry are now actively working on this" – the Deputy Prime Minister said. He added that now, in particular, work is being restored at the Angstrem plant.

According to Borisov, short-term stops of the conveyors of Russian automakers, in particular Avtovazaa, are not critical, because manufacturers have a stock of products.

In recent months, global automakers have been experiencing problems due to a shortage in the market of semiconductors and other automotive components. American General Motors, Japanese Toyota Motor, South Korean Hyundai Motor were forced to suspend the operation of some of their factories or reduce production volumes due to interruptions in the supply of chips.

The Association of European Businesses in Russia has previously stated that it expects a decline in sales volumes in Russia of most automakers this summer due to a shortage of electronic components around the world. The main Russian automaker, Avtovaz, has suspended production of various models of cars several times in recent months.

Source:

The Russian industry will not be able to replace all the scarce automotive components due to a lack of competencies for some products, but most of them will be able to. This opinion was expressed to journalists by Deputy Prime Minister of the Russian Federation Yuri Borisov on the sidelines of the Tyumen Oil and Gas Forum.

"Will the Russian industry be able to replace it? Potentially, it will be able to. Not on the entire product line, because we do not have the production assets of the necessary technological capabilities for the production of, say, high-tech microcontrollers and processors. This is a fact" – Borisov said. At the same time, he clarified that some of the products are gradually being replaced. "We have the necessary assets, where very high technologies in the field of power electronics are not required. Of course, these substitutions actually occur. So there is potential, and our enterprises are increasing volumes in this area" – he said, adding that this is a gradual process, and it is impossible to reach the required level of production at the same time.

According to Borisov, the shortage of automotive components affected not only Avtovaz and Kamaz, but also the main manufacturer of final automotive electronics, Itelma.

"The shortage of necessary components is experienced not only by Russia, but also by almost the entire global automotive industry. This is due to understandable reasons: the presence of an energy crisis associated with the pandemic, a sharp drop in production volumes, including in the global automotive industry, which led to the lack of demand for the necessary amount of all automotive components. Today we are getting out of this crisis. It is almost impossible to increase it at the same time, to reach the necessary level of production, this is a gradual process, the production capabilities of the entire global microelectronics industry are now actively working on this" – the Deputy Prime Minister said. He added that now, in particular, work is being restored at the Angstrem plant.

According to Borisov, short-term stops of the conveyors of Russian automakers, in particular Avtovazaa, are not critical, because manufacturers have a stock of products.

In recent months, global automakers have been experiencing problems due to a shortage in the market of semiconductors and other automotive components. American General Motors, Japanese Toyota Motor, South Korean Hyundai Motor were forced to suspend the operation of some of their factories or reduce production volumes due to interruptions in the supply of chips.

The Association of European Businesses in Russia has previously stated that it expects a decline in sales volumes in Russia of most automakers this summer due to a shortage of electronic components around the world. The main Russian automaker, Avtovaz, has suspended production of various models of cars several times in recent months.

Source:

GarryB likes this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°515

Re: Russian Auto Industry

Re: Russian Auto Industry

Niva from Switzerland: participants of the future Dakar visited AvtoVAZ.

The crew of the Swiss team Niva Red Legend Team visited AvtoVAZ — the sports Niva, prepared for participation in the Dakar-2021 rally raid, arrived in Togliatti on its own. As it was announced earlier, this team has secured the factory support of the domestic brand at the upcoming competition.

At the Russian enterprise, pilot Mario Jacober and navigator Ivan Milich visited the corporate museum and got acquainted with the sports Nivas that participated in Dakar in the old days - and which inspired the Swiss to take part in the legendary race themselves.

In addition, the crew visited the Lada Sport division, where the athletes talked with the president of AvtoVAZ, Nicolas Maure, and the director of Lada Sport, Vladislav Nezvankin. They were shown the car preparation shop of the Lada Sport Rosneft team and held a consultation on further refinement of the raid Niva.

Next, the Niva Red Legend Team will also go to Switzerland on its own, where the car will continue to be tuned before Dakar, the website "At the factory" reports. The car produced in 1984 is declared in the new category Dakar Classic, where cars produced before 2000 participate. According to the technical regulations of this category, cars must be equipped with a safety frame and racing seats, but all the technical stuffing must remain serial.

Source:

The crew of the Swiss team Niva Red Legend Team visited AvtoVAZ — the sports Niva, prepared for participation in the Dakar-2021 rally raid, arrived in Togliatti on its own. As it was announced earlier, this team has secured the factory support of the domestic brand at the upcoming competition.

At the Russian enterprise, pilot Mario Jacober and navigator Ivan Milich visited the corporate museum and got acquainted with the sports Nivas that participated in Dakar in the old days - and which inspired the Swiss to take part in the legendary race themselves.

In addition, the crew visited the Lada Sport division, where the athletes talked with the president of AvtoVAZ, Nicolas Maure, and the director of Lada Sport, Vladislav Nezvankin. They were shown the car preparation shop of the Lada Sport Rosneft team and held a consultation on further refinement of the raid Niva.

Next, the Niva Red Legend Team will also go to Switzerland on its own, where the car will continue to be tuned before Dakar, the website "At the factory" reports. The car produced in 1984 is declared in the new category Dakar Classic, where cars produced before 2000 participate. According to the technical regulations of this category, cars must be equipped with a safety frame and racing seats, but all the technical stuffing must remain serial.

Source:

PapaDragon and Mir like this post

Mir- Posts : 3837

Points : 3835

Join date : 2021-06-10

- Post n°516

Re: Russian Auto Industry

Re: Russian Auto Industry

www.zr.ru made a small mistake - it's preparation for Dakar-2022. Looking forward to follow these guys during the race.

flamming_python, PapaDragon and Russian_Patriot_ like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°517

Re: Russian Auto Industry

Re: Russian Auto Industry

The new Russian car: the first details about the E-NEVA model.

The Russian aerospace defense concern Almaz-Antey is developing a hybrid E-NEVA car with a gas-electric power plant for civilian use. This is reported by RBC with reference to its own sources familiar with the company's activities. The car will use hydrogen as fuel.

What Almaz-Antey produces

Almaz-Antey unites more than 60 enterprises specializing in the production of weapons for air and missile defense. Among the most famous developments of the Russian concern are the S-300 "Favorit", S-400 "Triumph" and S-500 "Prometheus" anti-aircraft missile systems. At the same time, Almaz-Antey is also engaged in the production of civilian products, mainly based on military developments in the field of management, topography and radar. The concern's peaceful arsenal includes, for example, automotive GLONASS navigators, as well as special equipment such as compact municipal harvesting machines and electric loaders.

In August 2021, a Russian missile developer at the Army-2021 forum presented a self-propelled electric platform on the basis of which it is possible to create passenger cars of various classes and with different types of drive. The chassis with a load capacity of up to 1650 kg includes two electric motors and a set of batteries with a capacity of 90 kWh, allowing you to drive about 400 kilometers without recharging. Plus, the platform provides for the installation of equipment for the unmanned control system, including ultrasonic sensors and lidars. The timing of the appearance of working cars was not indicated, but the release of the chassis for electric cars partially confirmed the previous unofficial information that Almaz-Antey is developing a prototype of an electric crossover.

What will E-NEVA be like

Now it has become known that the engineers of Almaz-Antey are working on creating a civil electric car with the working name E-NEVA, where the first letter is formed from the word "electric", and NEVA means a river in St. Petersburg. According to preliminary data, the model will have two main modifications. The first one will be a gas car with an electric transmission, which will be able to drive up to 1000 kilometers at one gas station. The second version will be an electric gas car with a 52-liter gas fuel system and batteries for 70 kWh, the stock of which can be replenished from the power grid. The autonomy of the course of such a car will be 810 kilometers. In both cases, the hybrid will be able to accelerate to "hundred" in 8.5 seconds, and its maximum speed is 180 km per hour.

"We already have an electric car, it drives. But we followed the path of creating a hybrid, where the main engine is on gas. At the same time, the energy generated during the movement will be accumulated, and electric traction will become an auxiliary energy source, the reserve of which will be enough for a certain number of kilometers" – Alexander Vedrov, Deputy Director for production and technological policy of Almaz — Antey, commented on RBC. He also clarified that the power plant with electric and gas engines assumes exclusively civilian use, since the military is not interested in using such a combination of units. The terms of implementation of the project and the size of investments are not yet called.

What other new cars are being developed in Russia

E-NEVA is not the only Russian project of a civilian car based on alternative energy sources. For example, in three years, the domestic luxury car manufacturer Aurus intends to release a car powered by hydrogen. Presumably, the novelty will be created on the basis of the government sedan Senat, whose gasoline-electric units will be replaced by a fuel-cell power plant. The car will be driven by electric motors, the energy for which is generated as a result of a chemical reaction between hydrogen and oxygen, and the only "exhaust" is ordinary water vapor.

In addition, KAMAZ is working on the creation of a compact electric car, which at the end of 2020 presented a prototype called "Kama-1". The model, which the company calls a "smart crossover", is equipped with a lithium-ion battery with a capacity of 33 kWh and an electric motor with a capacity of 80 kW (109 hp). The car is 3.4 m long and can take up to four people on board. Acceleration to the "hundred" takes the car 6.7 seconds, and the maximum speed is 150 km per hour. The declared power reserve is 250 kilometers. In the next 2-3 years, the model will undergo enhanced testing, and then it will be presented with the certification process. The electric car, ready for mass production, will be presented at the beginning of 2024.

Source:

The Russian aerospace defense concern Almaz-Antey is developing a hybrid E-NEVA car with a gas-electric power plant for civilian use. This is reported by RBC with reference to its own sources familiar with the company's activities. The car will use hydrogen as fuel.

What Almaz-Antey produces

Almaz-Antey unites more than 60 enterprises specializing in the production of weapons for air and missile defense. Among the most famous developments of the Russian concern are the S-300 "Favorit", S-400 "Triumph" and S-500 "Prometheus" anti-aircraft missile systems. At the same time, Almaz-Antey is also engaged in the production of civilian products, mainly based on military developments in the field of management, topography and radar. The concern's peaceful arsenal includes, for example, automotive GLONASS navigators, as well as special equipment such as compact municipal harvesting machines and electric loaders.

In August 2021, a Russian missile developer at the Army-2021 forum presented a self-propelled electric platform on the basis of which it is possible to create passenger cars of various classes and with different types of drive. The chassis with a load capacity of up to 1650 kg includes two electric motors and a set of batteries with a capacity of 90 kWh, allowing you to drive about 400 kilometers without recharging. Plus, the platform provides for the installation of equipment for the unmanned control system, including ultrasonic sensors and lidars. The timing of the appearance of working cars was not indicated, but the release of the chassis for electric cars partially confirmed the previous unofficial information that Almaz-Antey is developing a prototype of an electric crossover.

What will E-NEVA be like

Now it has become known that the engineers of Almaz-Antey are working on creating a civil electric car with the working name E-NEVA, where the first letter is formed from the word "electric", and NEVA means a river in St. Petersburg. According to preliminary data, the model will have two main modifications. The first one will be a gas car with an electric transmission, which will be able to drive up to 1000 kilometers at one gas station. The second version will be an electric gas car with a 52-liter gas fuel system and batteries for 70 kWh, the stock of which can be replenished from the power grid. The autonomy of the course of such a car will be 810 kilometers. In both cases, the hybrid will be able to accelerate to "hundred" in 8.5 seconds, and its maximum speed is 180 km per hour.

"We already have an electric car, it drives. But we followed the path of creating a hybrid, where the main engine is on gas. At the same time, the energy generated during the movement will be accumulated, and electric traction will become an auxiliary energy source, the reserve of which will be enough for a certain number of kilometers" – Alexander Vedrov, Deputy Director for production and technological policy of Almaz — Antey, commented on RBC. He also clarified that the power plant with electric and gas engines assumes exclusively civilian use, since the military is not interested in using such a combination of units. The terms of implementation of the project and the size of investments are not yet called.

What other new cars are being developed in Russia

E-NEVA is not the only Russian project of a civilian car based on alternative energy sources. For example, in three years, the domestic luxury car manufacturer Aurus intends to release a car powered by hydrogen. Presumably, the novelty will be created on the basis of the government sedan Senat, whose gasoline-electric units will be replaced by a fuel-cell power plant. The car will be driven by electric motors, the energy for which is generated as a result of a chemical reaction between hydrogen and oxygen, and the only "exhaust" is ordinary water vapor.

In addition, KAMAZ is working on the creation of a compact electric car, which at the end of 2020 presented a prototype called "Kama-1". The model, which the company calls a "smart crossover", is equipped with a lithium-ion battery with a capacity of 33 kWh and an electric motor with a capacity of 80 kW (109 hp). The car is 3.4 m long and can take up to four people on board. Acceleration to the "hundred" takes the car 6.7 seconds, and the maximum speed is 150 km per hour. The declared power reserve is 250 kilometers. In the next 2-3 years, the model will undergo enhanced testing, and then it will be presented with the certification process. The electric car, ready for mass production, will be presented at the beginning of 2024.

Source:

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°518

Re: Russian Auto Industry

Re: Russian Auto Industry

PapaDragon likes this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°519

Re: Russian Auto Industry

Re: Russian Auto Industry

Production of Lada cars will be launched in Ethiopia.

Ethiopia can establish the production of cars of the Russian Lada brand. This is reported by the press service of the local company Bazra Motors, which has agreed with AvtoVAZ on the purchase of car kits from Russia.

Bazra Motors notes that the cars of the Russian brand are familiar to Ethiopians from the VAZ-2105 model, which appeared in the African country in 1974. The cars were used by civil servants and the military, and also consisted of taxi fleets.

Ethiopia intends to produce the entire current line of Lada cars, including Granta, Vesta, Xray, Largus, Niva Travel and Niva Legend. Production will be established at the enterprise in the city of Kombolcha (Amhara state). At the initial stage, Bazra Motors plans to produce 5 thousand cars a year, and in five years to reach the figure of 10 thousand cars produced annually.

In April 2021, during an official visit to Ethiopia, the UAZ delegation reached an agreement with Bazra Motors on the organization of the assembly of Russian SUVs on the territory of the East African state.

At the same factory in Kombolche, they should organize the production of all versions of Patriot SUVs, light trucks "Profi" and "Pickup", as well as classic models "Hunter" and SGR ("Bukhanka"). At the same time, in the future, the model line can be supplemented with special modifications of cars designed specifically taking into account the Ethiopian market.

Source:

Ethiopia can establish the production of cars of the Russian Lada brand. This is reported by the press service of the local company Bazra Motors, which has agreed with AvtoVAZ on the purchase of car kits from Russia.

Bazra Motors notes that the cars of the Russian brand are familiar to Ethiopians from the VAZ-2105 model, which appeared in the African country in 1974. The cars were used by civil servants and the military, and also consisted of taxi fleets.

Ethiopia intends to produce the entire current line of Lada cars, including Granta, Vesta, Xray, Largus, Niva Travel and Niva Legend. Production will be established at the enterprise in the city of Kombolcha (Amhara state). At the initial stage, Bazra Motors plans to produce 5 thousand cars a year, and in five years to reach the figure of 10 thousand cars produced annually.

In April 2021, during an official visit to Ethiopia, the UAZ delegation reached an agreement with Bazra Motors on the organization of the assembly of Russian SUVs on the territory of the East African state.

At the same factory in Kombolche, they should organize the production of all versions of Patriot SUVs, light trucks "Profi" and "Pickup", as well as classic models "Hunter" and SGR ("Bukhanka"). At the same time, in the future, the model line can be supplemented with special modifications of cars designed specifically taking into account the Ethiopian market.

Source:

flamming_python and Daniel_Admassu like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°520

Re: Russian Auto Industry

Re: Russian Auto Industry

Interview with Deputy Head of the Ministry of Industry and Trade Alexander Morozov.

– The government has approved the concept of the development of electric transport in the country until 2030. Is Russia officially heading for the mass creation of electric cars and cars powered by hydrogen?

– The goals that the government is facing are not just to create electric cars or hydrogen-powered cars and make our life more comfortable and environmentally friendly. They are much wider. It is, in fact, about the creation of new innovative industries.

If you look globally, electric, hydrogen, unmanned, data exchange and storage technologies are the main directions for development and investment in the industry.

– Global automakers invest an order of magnitude more money in startups and innovations than Russian automakers. What do you associate this with?

– Do you think that we really do not have the opportunity and interest from our concerns? Do we have such a weak scientific base in Russia? Of course not. Investments in innovative transport, as a rule, require the participation of two parties – the investor and the state. The concept for the development of production and use of electric motor transport until 2030 is a government proposal for global and Russian automakers to jointly develop the innovative transport market. If you want to participate – and all manufacturers have an ambitious goal to expand their presence in regional markets – you should invest. The state, for its part, should create conditions for supporting investments. What, as a rule, is state support? Either in reducing taxes, or in subsidizing.

– According to your calculations, after the approval of the concept, how much should the volume of investments by the Russian automotive industry in the development of these technologies increase?

– Next year, an order of magnitude more.

– What budgets are included in the concept on the part of the state?

– The project budget is not collected in any one budget line, it is distributed among the ministries. Part of the state support will be provided by the Ministry of Energy. This is the development of the gas station infrastructure: both electric gas stations and hydrogen ones. Part of it will be from the Ministry of Industry and Trade. Here we are talking about creating production facilities for electric cars and hydrogen cars, creating production facilities for key components: fuel cells, batteries, power electronics and stimulating demand. Another participant is the Ministry of Transport. Behind it is the road infrastructure – sensors, telemetry tools. In general, there are many participants in the concept. For example, Rosatom sees itself as an investor in the production of hydrogen fuel cells and batteries, Gazprom – an investor in the production of hydrogen purification, oil companies – hydrogen production.

– Is the Ministry of Industry and Trade developing new programs to support the demand for electric cars?

– There are no fundamentally new programs planned, but the existing ones will be expanded: new sections will appear inside them. For example, we have a program of preferential car loans, in which electric cars will appear from next year. In addition, another important document is currently being prepared for release – on the implementation of the component development program. It will formulate the rules of state support for private companies investing in the creation of plants for the production of high-tech components.

– That is, new factories will be built in the country, which will provide a component base for electric cars and hydrogen-powered cars?

– Exactly. There will be a plant for the production of fuel cells, a plant for the production of power electronics, a plant for the production of battery cells. This is what we are currently missing.

– In what time frame?

– By 2024, we must conclude special investment contracts with investors. This means that the plants will begin to be built, and private investors will assume the corresponding obligations to the state. But this is only the first direction, you can't go on one fuel cell. The second is the production of electric cars and hydrogen-powered cars themselves. In fact, automakers have two options: to use existing capacities and produce electric cars on them, or to build specialized new plants for their production.

– Have any of the automakers already discussed such plans with you?

– The application was made by Kamaz. Do you remember the electric car "Kama"? Kamaz already has experience in the production of electric buses, and they are discussing the launch of the plant in 2024-2025. I must say that today Moscow is the main interestant and driver of this process.

– A separate plant for the production of "Kama"?

– Yes, specifically for "Kama". I think it will be like this. The dimension of a small car and a large Kamaz is too different. In the near future, we will follow the news from the company with interest, they are now waiting for the shareholders' decision and will be determined with the site. I think it will be a small factory, the production of electric cars is a very compact story.

– AvtoVAZ also has experience in the production of electric cars – the same Lada Ellada. Don't they also want, as you said, to "reincarnate" this experience?

– AvtoVAZ is currently studying this issue. By the way, in their opinion, the determining factor in making a decision is the "density" of electric gas stations. If you can only drive in the center of one city, you will probably still think about buying an electric car or not. Speaking of key highways, it is quite simple to electrify them for the transportation of goods. As soon as we turn to cars of individuals, the number one issue is not the production of cars, but the presence of an extensive network of fast gas stations.

– Are these all interested parties?

– So, we were talking about Kamaz, there is also Motorinvest in the Lipetsk region. At one time, it was globally supported by Rosseti. I hope that the Lipetsk company will sign a special investment contract with us on the production of electric vehicles at its full-cycle plant, which has already been built. Next comes a very ambitious company "Avtotor", which is located in Kaliningrad. This is our westernmost outpost. The company has already made proposals to amend the special investment contract to add various innovative modes of transport to it, among other things. The interdepartmental commission will soon consider changes to the special investment contract of Avtotor.

– And the Zetta electric car? Has its certification been completed yet?

- In the process. Zetta plans to receive a safety certificate in the L-7 category, that is, as a lightweight vehicle.

– You have listed many car manufacturers who are thinking about the production of electric cars in Russia. In your opinion, who will be the first in this race?

– I think that the project from Lipetsk will be the fastest to enter the market. Zetta will be running on his heels (provided that additional investments are attracted to the project). Then, I think, there will be "Kama". And all this in the next two or three years.

- It is interesting that new brands are among the leaders…

– True, but what is the meaning of electric mobility? The fact that the number of projects for the production of electric vehicles will grow significantly. We now know about 100 brands of cars, as we switch to electricity, their number will be a thousand, you'll see. What is the reason? For example, a traditional automaker has spent a huge amount of time and money on the production of an internal combustion engine, an automatic transmission. To do this, it takes not only people – it takes years. Now we take an electric car. The internal combustion engine and automatic transmission do not need to be developed. What's left? (Wheels, brakes, seats, windows are not counted). There was a battery, an electric motor and a control system for them. This means that today the company can quickly organize the assembly of electric vehicles, if it agrees with the suppliers of components, assembling a kind of "constructor" from the available components and assemblies.

– The BMW carmaker has been thinking about building its own plant in Russia for several years. In your opinion, the approval of the concept of electric transport development can accelerate this decision?

– I know what intense negotiations they are conducting with their partner in the person of Avtotor, with a number of Russian regions. Plus, the territory of the Kaliningrad Region is historically very important for BMW. Therefore, I think that very "green" news is waiting for us soon.

– Turning to hydrogen transport, has anyone already discussed with you the possibility of localizing such production in the passenger segment?

– A hydrogen car in its essence is an electric car. What is the difference between a hydrogen car and an electric one? In the case of an electric car, the wheels are driven by an electric motor that receives energy from a large traction electric battery. In the case of a hydrogen car, the energy source is not a traction battery (although there is an electric battery, but a small one), but a hydrogen fuel cell that turns gas (hydrogen) into electricity. That is, they have a common electric platform, but the difference is fundamental. In the case of an electric car, we store electrical energy in the form of a chemical reaction. There are pros and cons here. The disadvantages include a very high dependence of this energy source on the ambient temperature. As you know, with each decrease in temperature by 10 degrees, the speed of the chemical reaction drops by 2-4 times. When it is minus 20 outside, as it was last winter, the efficiency of the electric battery drops sharply, because the speed of the chemical reaction decreases many times. Taking into account our climatic conditions, hydrogen will be more promising for commercial trunk transport. Plus, the mileage (power reserve) of a hydrogen car is much more than an electric one.

– What else does the approval of the concept of electric transport development bring to the industry?

– Another important task, if we want to become a country that participates in the technological race, is our own testing and certification base for electric cars, fuel cells and other components. For this purpose, it is planned to create a research and certification center in Russia, where any manufacturer of cars or components will be able to pass international certification.

Source:

– The government has approved the concept of the development of electric transport in the country until 2030. Is Russia officially heading for the mass creation of electric cars and cars powered by hydrogen?

– The goals that the government is facing are not just to create electric cars or hydrogen-powered cars and make our life more comfortable and environmentally friendly. They are much wider. It is, in fact, about the creation of new innovative industries.

If you look globally, electric, hydrogen, unmanned, data exchange and storage technologies are the main directions for development and investment in the industry.

– Global automakers invest an order of magnitude more money in startups and innovations than Russian automakers. What do you associate this with?

– Do you think that we really do not have the opportunity and interest from our concerns? Do we have such a weak scientific base in Russia? Of course not. Investments in innovative transport, as a rule, require the participation of two parties – the investor and the state. The concept for the development of production and use of electric motor transport until 2030 is a government proposal for global and Russian automakers to jointly develop the innovative transport market. If you want to participate – and all manufacturers have an ambitious goal to expand their presence in regional markets – you should invest. The state, for its part, should create conditions for supporting investments. What, as a rule, is state support? Either in reducing taxes, or in subsidizing.

– According to your calculations, after the approval of the concept, how much should the volume of investments by the Russian automotive industry in the development of these technologies increase?

– Next year, an order of magnitude more.

– What budgets are included in the concept on the part of the state?

– The project budget is not collected in any one budget line, it is distributed among the ministries. Part of the state support will be provided by the Ministry of Energy. This is the development of the gas station infrastructure: both electric gas stations and hydrogen ones. Part of it will be from the Ministry of Industry and Trade. Here we are talking about creating production facilities for electric cars and hydrogen cars, creating production facilities for key components: fuel cells, batteries, power electronics and stimulating demand. Another participant is the Ministry of Transport. Behind it is the road infrastructure – sensors, telemetry tools. In general, there are many participants in the concept. For example, Rosatom sees itself as an investor in the production of hydrogen fuel cells and batteries, Gazprom – an investor in the production of hydrogen purification, oil companies – hydrogen production.

– Is the Ministry of Industry and Trade developing new programs to support the demand for electric cars?

– There are no fundamentally new programs planned, but the existing ones will be expanded: new sections will appear inside them. For example, we have a program of preferential car loans, in which electric cars will appear from next year. In addition, another important document is currently being prepared for release – on the implementation of the component development program. It will formulate the rules of state support for private companies investing in the creation of plants for the production of high-tech components.

– That is, new factories will be built in the country, which will provide a component base for electric cars and hydrogen-powered cars?

– Exactly. There will be a plant for the production of fuel cells, a plant for the production of power electronics, a plant for the production of battery cells. This is what we are currently missing.

– In what time frame?

– By 2024, we must conclude special investment contracts with investors. This means that the plants will begin to be built, and private investors will assume the corresponding obligations to the state. But this is only the first direction, you can't go on one fuel cell. The second is the production of electric cars and hydrogen-powered cars themselves. In fact, automakers have two options: to use existing capacities and produce electric cars on them, or to build specialized new plants for their production.

– Have any of the automakers already discussed such plans with you?

– The application was made by Kamaz. Do you remember the electric car "Kama"? Kamaz already has experience in the production of electric buses, and they are discussing the launch of the plant in 2024-2025. I must say that today Moscow is the main interestant and driver of this process.

– A separate plant for the production of "Kama"?

– Yes, specifically for "Kama". I think it will be like this. The dimension of a small car and a large Kamaz is too different. In the near future, we will follow the news from the company with interest, they are now waiting for the shareholders' decision and will be determined with the site. I think it will be a small factory, the production of electric cars is a very compact story.

– AvtoVAZ also has experience in the production of electric cars – the same Lada Ellada. Don't they also want, as you said, to "reincarnate" this experience?

– AvtoVAZ is currently studying this issue. By the way, in their opinion, the determining factor in making a decision is the "density" of electric gas stations. If you can only drive in the center of one city, you will probably still think about buying an electric car or not. Speaking of key highways, it is quite simple to electrify them for the transportation of goods. As soon as we turn to cars of individuals, the number one issue is not the production of cars, but the presence of an extensive network of fast gas stations.

– Are these all interested parties?

– So, we were talking about Kamaz, there is also Motorinvest in the Lipetsk region. At one time, it was globally supported by Rosseti. I hope that the Lipetsk company will sign a special investment contract with us on the production of electric vehicles at its full-cycle plant, which has already been built. Next comes a very ambitious company "Avtotor", which is located in Kaliningrad. This is our westernmost outpost. The company has already made proposals to amend the special investment contract to add various innovative modes of transport to it, among other things. The interdepartmental commission will soon consider changes to the special investment contract of Avtotor.

– And the Zetta electric car? Has its certification been completed yet?

- In the process. Zetta plans to receive a safety certificate in the L-7 category, that is, as a lightweight vehicle.

– You have listed many car manufacturers who are thinking about the production of electric cars in Russia. In your opinion, who will be the first in this race?

– I think that the project from Lipetsk will be the fastest to enter the market. Zetta will be running on his heels (provided that additional investments are attracted to the project). Then, I think, there will be "Kama". And all this in the next two or three years.

- It is interesting that new brands are among the leaders…

– True, but what is the meaning of electric mobility? The fact that the number of projects for the production of electric vehicles will grow significantly. We now know about 100 brands of cars, as we switch to electricity, their number will be a thousand, you'll see. What is the reason? For example, a traditional automaker has spent a huge amount of time and money on the production of an internal combustion engine, an automatic transmission. To do this, it takes not only people – it takes years. Now we take an electric car. The internal combustion engine and automatic transmission do not need to be developed. What's left? (Wheels, brakes, seats, windows are not counted). There was a battery, an electric motor and a control system for them. This means that today the company can quickly organize the assembly of electric vehicles, if it agrees with the suppliers of components, assembling a kind of "constructor" from the available components and assemblies.

– The BMW carmaker has been thinking about building its own plant in Russia for several years. In your opinion, the approval of the concept of electric transport development can accelerate this decision?

– I know what intense negotiations they are conducting with their partner in the person of Avtotor, with a number of Russian regions. Plus, the territory of the Kaliningrad Region is historically very important for BMW. Therefore, I think that very "green" news is waiting for us soon.

– Turning to hydrogen transport, has anyone already discussed with you the possibility of localizing such production in the passenger segment?

– A hydrogen car in its essence is an electric car. What is the difference between a hydrogen car and an electric one? In the case of an electric car, the wheels are driven by an electric motor that receives energy from a large traction electric battery. In the case of a hydrogen car, the energy source is not a traction battery (although there is an electric battery, but a small one), but a hydrogen fuel cell that turns gas (hydrogen) into electricity. That is, they have a common electric platform, but the difference is fundamental. In the case of an electric car, we store electrical energy in the form of a chemical reaction. There are pros and cons here. The disadvantages include a very high dependence of this energy source on the ambient temperature. As you know, with each decrease in temperature by 10 degrees, the speed of the chemical reaction drops by 2-4 times. When it is minus 20 outside, as it was last winter, the efficiency of the electric battery drops sharply, because the speed of the chemical reaction decreases many times. Taking into account our climatic conditions, hydrogen will be more promising for commercial trunk transport. Plus, the mileage (power reserve) of a hydrogen car is much more than an electric one.

– What else does the approval of the concept of electric transport development bring to the industry?

– Another important task, if we want to become a country that participates in the technological race, is our own testing and certification base for electric cars, fuel cells and other components. For this purpose, it is planned to create a research and certification center in Russia, where any manufacturer of cars or components will be able to pass international certification.

Source:

dino00 likes this post

Daniel_Admassu- Posts : 149

Points : 151

Join date : 2020-11-18

Age : 44

Location : Addis Ababa, Ethiopia

- Post n°521

Re: Russian Auto Industry

Re: Russian Auto Industry

Russian_Patriot_ wrote:Production of Lada cars will be launched in Ethiopia.

Ethiopia can establish the production of cars of the Russian Lada brand. This is reported by the press service of the local company Bazra Motors, which has agreed with AvtoVAZ on the purchase of car kits from Russia.

Bazra Motors notes that the cars of the Russian brand are familiar to Ethiopians from the VAZ-2105 model, which appeared in the African country in 1974. The cars were used by civil servants and the military, and also consisted of taxi fleets.

Ethiopia intends to produce the entire current line of Lada cars, including Granta, Vesta, Xray, Largus, Niva Travel and Niva Legend. Production will be established at the enterprise in the city of Kombolcha (Amhara state). At the initial stage, Bazra Motors plans to produce 5 thousand cars a year, and in five years to reach the figure of 10 thousand cars produced annually.

In April 2021, during an official visit to Ethiopia, the UAZ delegation reached an agreement with Bazra Motors on the organization of the assembly of Russian SUVs on the territory of the East African state.

At the same factory in Kombolche, they should organize the production of all versions of Patriot SUVs, light trucks "Profi" and "Pickup", as well as classic models "Hunter" and SGR ("Bukhanka"). At the same time, in the future, the model line can be supplemented with special modifications of cars designed specifically taking into account the Ethiopian market.

Source:

Great news. The Autovaz Lada 2100 series has indeed been a popular cab transport in Ethiopia for the past 40 years or so. In fact the term 'Lada' is synonymous with cab transport here. They were imported during the 1974-1990 socialist government. Most were second hand models even then. They still are going strong thanks to their high maintainability and their rugged suspension being suitable for the local road conditions. Lately cheap modern Chinese sedans have been invading the cab market. And no surprises, they have been breaking down and bankrupting their owners. I was wandering if indeed modern versions of the Lada would make a comeback to the country.

dino00 and kvs like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°522

Re: Russian Auto Industry

Re: Russian Auto Industry

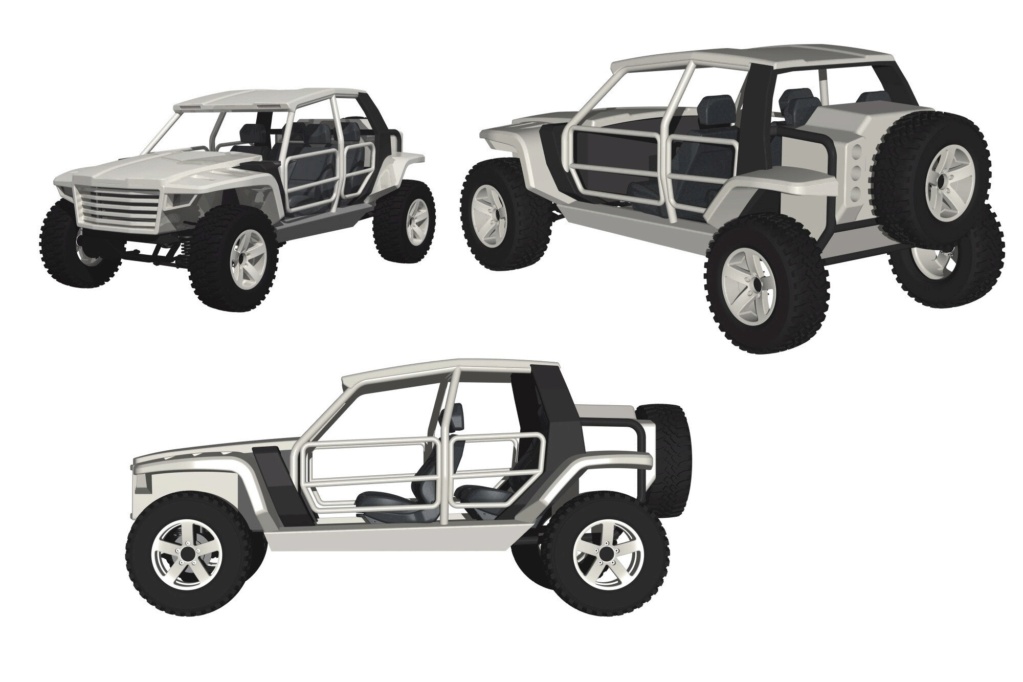

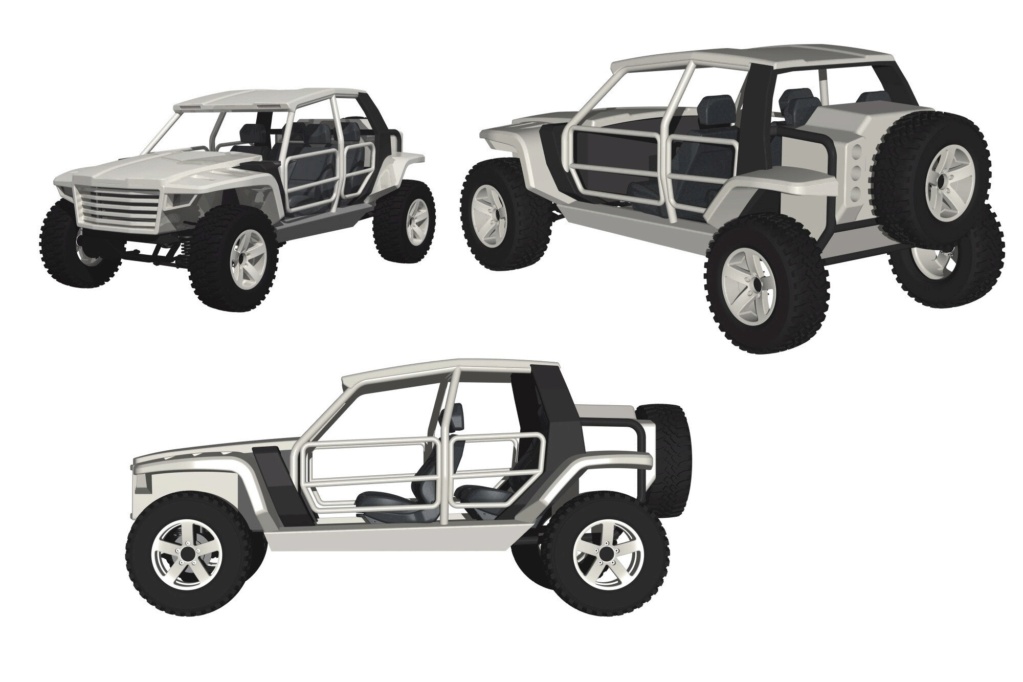

In Togliatti, a buggy based on Lada Niva was designed.

Togliatti State University together with the tuning attele F-Design has developed a buggy based on Lada Niva. This is reported by the public "Russian Car" in the social network "VKontakte" with reference to the data of the Federal Institute of Industrial Property (FIPS), where the design of the car was patented. It is still unknown whether the car will go into mass production.

Judging by the images, the buggy received mud tires, a plastic roof and a small trunk. The car has no traditional doors, and the car also has no windows.

The technical characteristics of the new product are unknown. The standard Lada Niva SUV is equipped with a 1.7-liter gasoline engine that develops 83 hp and 129 Nm of torque. The engine is paired with a five-speed manual transmission and all-wheel drive.

Togliatti State University together with the tuning attele F-Design has developed a buggy based on Lada Niva. This is reported by the public "Russian Car" in the social network "VKontakte" with reference to the data of the Federal Institute of Industrial Property (FIPS), where the design of the car was patented. It is still unknown whether the car will go into mass production.

Judging by the images, the buggy received mud tires, a plastic roof and a small trunk. The car has no traditional doors, and the car also has no windows.

The technical characteristics of the new product are unknown. The standard Lada Niva SUV is equipped with a 1.7-liter gasoline engine that develops 83 hp and 129 Nm of torque. The engine is paired with a five-speed manual transmission and all-wheel drive.

flamming_python and Mir like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°523

Re: Russian Auto Industry

Re: Russian Auto Industry

Avtotor will release its own car for 1.5 million rubles.

In 2023, the holding will release an experimental batch of 200 copies. A year later, 1000 cars will be assembled.

Kaliningrad "Avtotor" will establish the production of electric vehicles of its own design. The founder of the holding, Vladimir Shcherbakov, told about this during a meeting on September 24 with the head of the Ministry of Industry and Trade of Russia, Denis Manturov.

Initially, the company intends to produce two electric models. In electric cars, components of domestic production are used.

"We have an obligation to put up an experimental batch in 2023, this one in 2024" – Shcherbakov said, presenting promising projects to Manturov.

In 2023, the first batch (200 cars) of Kaliningrad electric vehicles will be manufactured. In 2024, the assembly of commodity samples will start. Then the circulation of electric cars will already be 1000 copies.

The approximate cost of an electric car is 1,500,000 rubles. This limit depends on the volume of production, the terms of delivery of components and other factors. While the power reserve of the model reaches 180 km. In three years, the range will be brought to 400 km. After all, design and technological changes will allow creating an upgraded modification of the model, including with a gas and electric motor.

Moreover, Avtotor plans to create a whole model range on a single platform, which will also include a minibus, a pickup truck and a version for people with disabilities.

Source:

In 2023, the holding will release an experimental batch of 200 copies. A year later, 1000 cars will be assembled.

Kaliningrad "Avtotor" will establish the production of electric vehicles of its own design. The founder of the holding, Vladimir Shcherbakov, told about this during a meeting on September 24 with the head of the Ministry of Industry and Trade of Russia, Denis Manturov.

Initially, the company intends to produce two electric models. In electric cars, components of domestic production are used.

"We have an obligation to put up an experimental batch in 2023, this one in 2024" – Shcherbakov said, presenting promising projects to Manturov.

In 2023, the first batch (200 cars) of Kaliningrad electric vehicles will be manufactured. In 2024, the assembly of commodity samples will start. Then the circulation of electric cars will already be 1000 copies.

The approximate cost of an electric car is 1,500,000 rubles. This limit depends on the volume of production, the terms of delivery of components and other factors. While the power reserve of the model reaches 180 km. In three years, the range will be brought to 400 km. After all, design and technological changes will allow creating an upgraded modification of the model, including with a gas and electric motor.

Moreover, Avtotor plans to create a whole model range on a single platform, which will also include a minibus, a pickup truck and a version for people with disabilities.

Source:

GarryB and flamming_python like this post

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°524

Re: Russian Auto Industry

Re: Russian Auto Industry

An autopilot will appear on Aurus – first it will be tested on Vesta.

Russian executive cars will receive the second and third levels of autonomy.

The Aurus developer has started working on its own autopilot, which will begin with the second and third levels of automation. The unmanned system will include adaptive cruise control, an emergency braking function, and an assistant for automatic obstacle avoidance.

As reported by "Gazeta.Ru", WE have allocated 38.7 million rubles for a promising project. The development of the autopilot will be carried out in three stages and will be completed by 2023. The stages include the creation and testing of the above-mentioned electronic assistants.

The Lada Vesta Sedan with a 1.6-liter engine and CVT will become a test instance for the complex of the domestic active safety system. The technical characteristics specified in the request for quotations correspond to this version of the model in all parameters. Note that the above-mentioned Vesta from the factory costs 933,900 rubles.

The Russian autopilot should receive models of the premium brand Aurus. At the moment, there are already electronic assistants in the arsenal of Aurus Senat, but from third-party developers. It is unlikely that the autopilot from NAMI will appear in Lada cars. After all, all purchases at AvtoVAZ are carried out by the Renault–Nissan–Mitsubishi Alliance.

Source:

Russian executive cars will receive the second and third levels of autonomy.

The Aurus developer has started working on its own autopilot, which will begin with the second and third levels of automation. The unmanned system will include adaptive cruise control, an emergency braking function, and an assistant for automatic obstacle avoidance.

As reported by "Gazeta.Ru", WE have allocated 38.7 million rubles for a promising project. The development of the autopilot will be carried out in three stages and will be completed by 2023. The stages include the creation and testing of the above-mentioned electronic assistants.

The Lada Vesta Sedan with a 1.6-liter engine and CVT will become a test instance for the complex of the domestic active safety system. The technical characteristics specified in the request for quotations correspond to this version of the model in all parameters. Note that the above-mentioned Vesta from the factory costs 933,900 rubles.

The Russian autopilot should receive models of the premium brand Aurus. At the moment, there are already electronic assistants in the arsenal of Aurus Senat, but from third-party developers. It is unlikely that the autopilot from NAMI will appear in Lada cars. After all, all purchases at AvtoVAZ are carried out by the Renault–Nissan–Mitsubishi Alliance.

Source:

Russian_Patriot_- Posts : 1286

Points : 1300

Join date : 2021-06-08

- Post n°525

Re: Russian Auto Industry

Re: Russian Auto Industry

The first KAMAZ K5 trucks were assembled in Kazakhstan.

New KAMAZ tractors of the K5 generation have been sold in Russia for more than a year — and they are already actively flashing on our roads in the ranks of their own kind. Not so long ago, we told that these machines began to be delivered to the CIS countries: the first copies have already been sold in Belarus and Uzbekistan. Well, Kazakhstan went even further — the assembly of new tractors was organized in this country.

So far, five samples of K5 family tractors have been collected at the joint Kazakh-Russian KAMAZ-Engineering enterprise in the city of Kokshetau. These machines are equipped with 450-horsepower engines and ZF robotic boxes. They are assembled by the large-node method — and will be delivered to local dealers as demonstration samples. It is likely that in the future a similar assembly of client machines will be established immediately.

The assembly plant itself in Kokshetau is considered, by local standards, quite modern. However, its main products are KAMAZ trucks with old cabs of the K3 generation-dump trucks and truck tractors of different weight and power capabilities.

Source:

New KAMAZ tractors of the K5 generation have been sold in Russia for more than a year — and they are already actively flashing on our roads in the ranks of their own kind. Not so long ago, we told that these machines began to be delivered to the CIS countries: the first copies have already been sold in Belarus and Uzbekistan. Well, Kazakhstan went even further — the assembly of new tractors was organized in this country.

So far, five samples of K5 family tractors have been collected at the joint Kazakh-Russian KAMAZ-Engineering enterprise in the city of Kokshetau. These machines are equipped with 450-horsepower engines and ZF robotic boxes. They are assembled by the large-node method — and will be delivered to local dealers as demonstration samples. It is likely that in the future a similar assembly of client machines will be established immediately.

The assembly plant itself in Kokshetau is considered, by local standards, quite modern. However, its main products are KAMAZ trucks with old cabs of the K3 generation-dump trucks and truck tractors of different weight and power capabilities.

Source:

PapaDragon likes this post