LMFS wrote:Interview with USC's Rakhmanov covering the current status of naval construction in Russia:

https://tvzvezda.ru/news/opk/content/2020723154-dlfmj.html

"There are 14 ships in our delivery program": an interview with the head of USC Alexei Rakhmanov on the Day of the Navy

The United Shipbuilding Corporation (USC) expects to deliver 14 ships by the end of the year.

The head of the United Shipbuilding Corporation, Alexei Rakhmanov, summed up the preliminary results of the current year in an interview with Zvezda, spoke about the work on the 885 project, optimization of production at USC enterprises and the development of shipbuilding in the Far East.

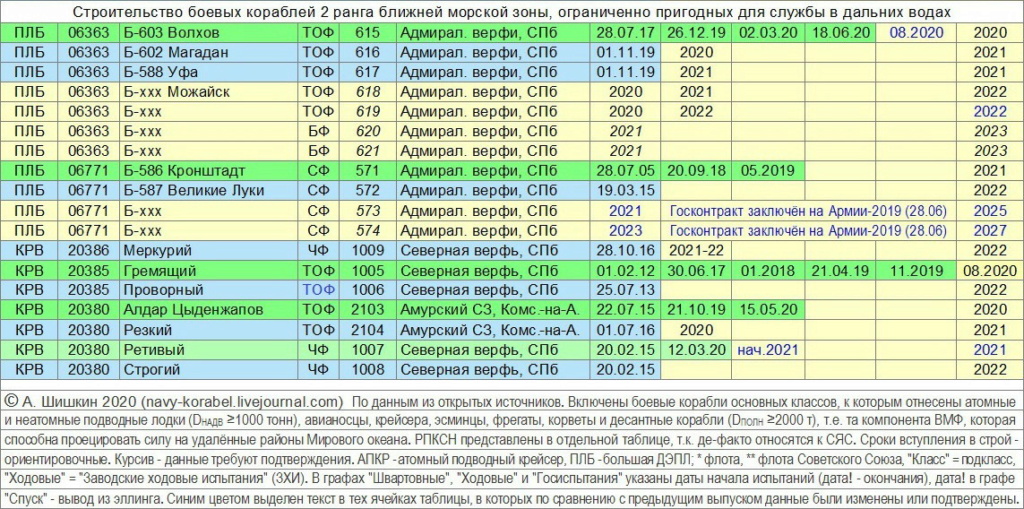

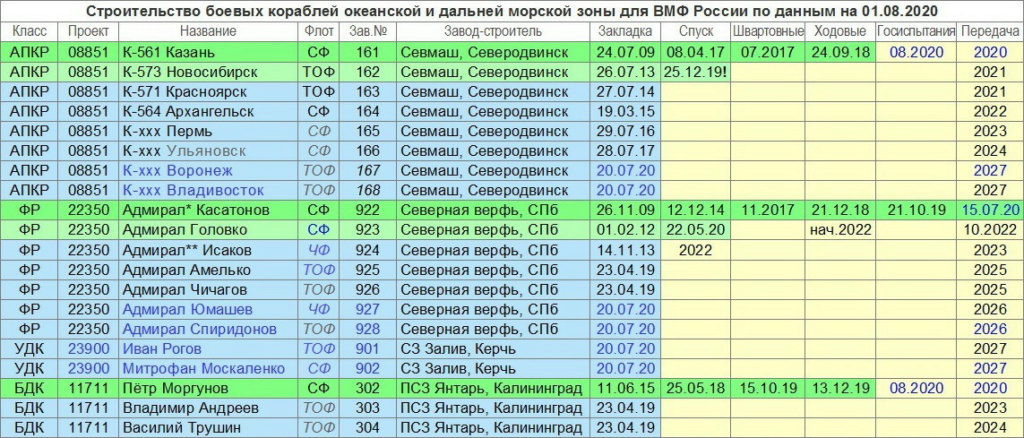

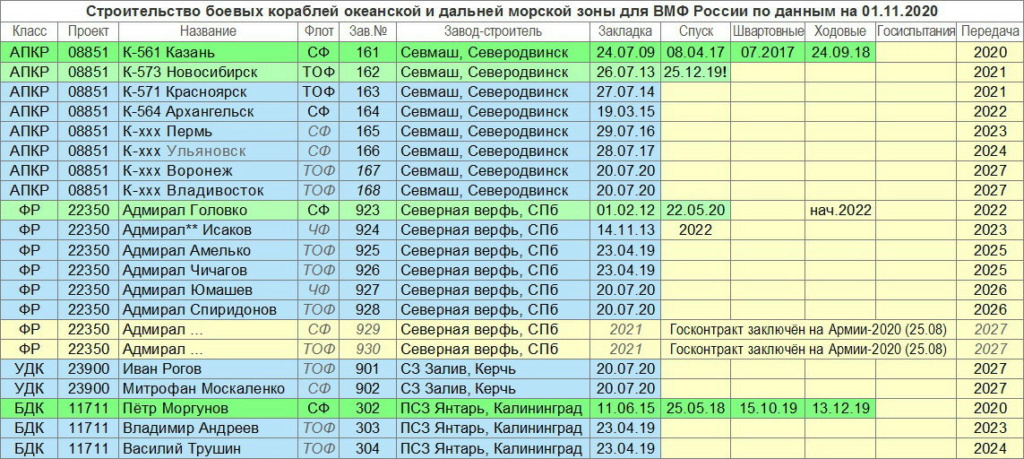

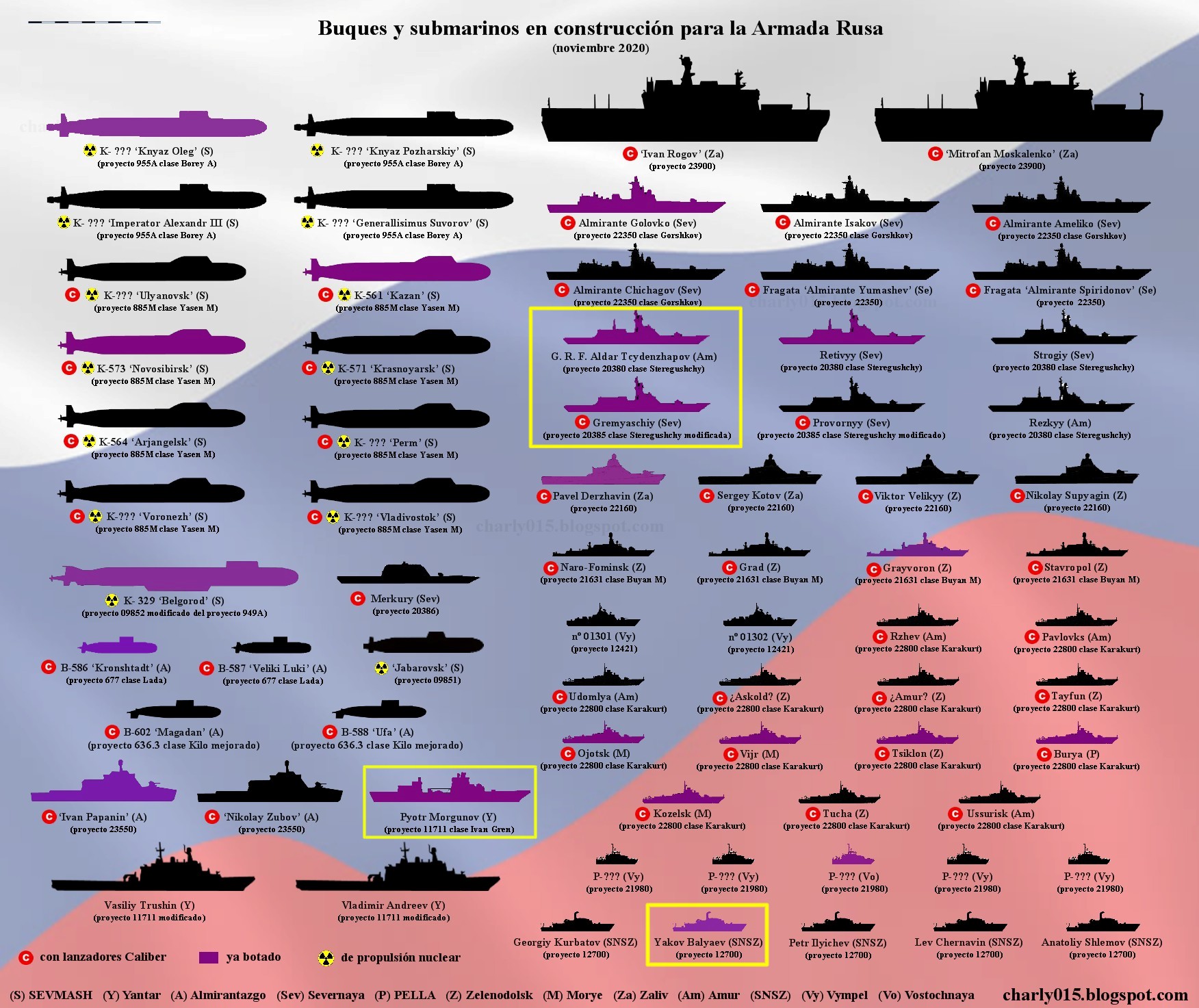

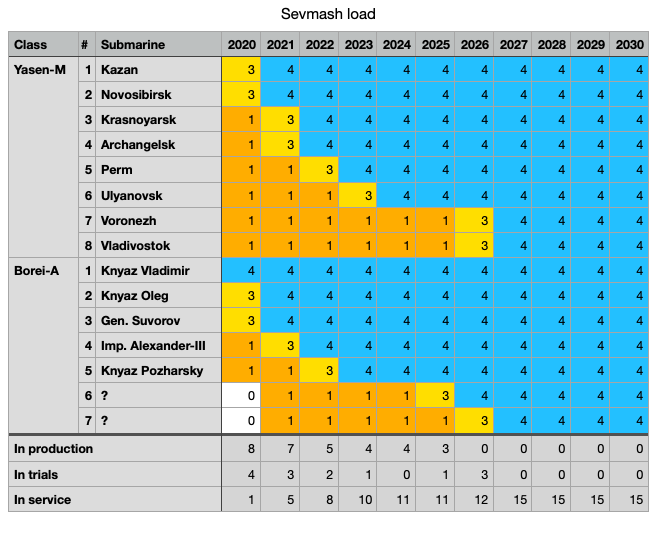

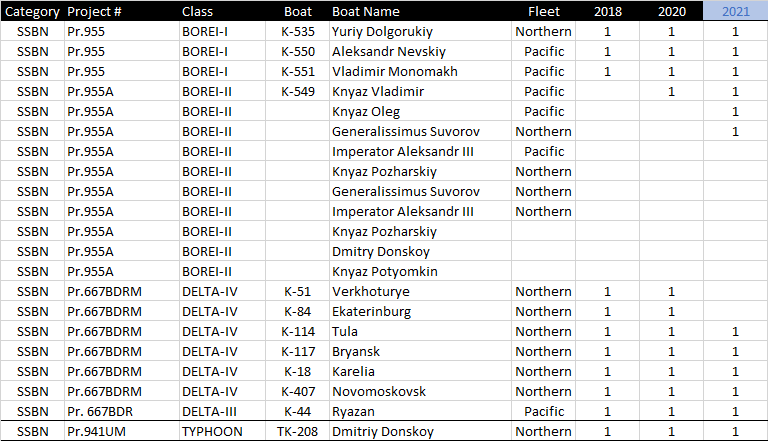

On the twenty-sixth of July, Russia celebrates the Day of the Navy. What has been done by USC for the fleet since the beginning of this year, and what ships and submarines are planned to be commissioned by December 31?In our delivery program there are 14 ships - from construction and from repair. Some of them have already been transferred to the Navy this year. In this regard, we are trying very hard not to disrupt the delivery schedules of key warships and escort vessels, but at the same time there are problems associated with the fact that we are working very carefully on the lead ships. For example, a typical example in this sense will be "Prince Vladimir" - another nuclear missile carrier, which was transferred to the Russian Navy on the Day of Russia, when we, in fact, completed all the main tests last year and brought it to the state of an almost finished combat unit , capable of joining the forces in full combat readiness at the beginning of this year.

This is, in a sense, a new practice for us, since, as a rule, the final steps were accompanied by, let's say, "fine tuning" of this missile carrier. Imagine yourself, we are doing repairs in the apartment, and now the walls are ready, and the windows are up, and the parquet flooring and chandeliers have been hung, but after that the following story begins: here is a hook to hang, here is a mirror, here are pictures. In this sense, we were doing something similar to this procedure, although of course we should have passed the order last year, but I repeat once again, he completely completed state tests last year, so here we acted exclusively in agreement with the Navy and with Ministry of Defense.

Next we have the next frigate of the "Admiral Gorshkov" class at the exit. We have handed over two tugboats at the Astrakhan shipyard; tests of our serial submarines are at the final stage. And the most important thing, perhaps, what we are doing on Project 885 is just entering the most difficult time after the completion of those comments that were identified in navigation last year - testing of key strike weapons on this project.

A very difficult, I would even say, a record year awaits us, since we have probably not handed over such a number of warships and in particular submarines since Soviet times. This topic is very important for us, because in this difficult year it demanded a huge mobilization of labor, engineering, human resources in order to pile up the whole world and fulfill the state defense order of this year to the maximum extent.

How are the programs for building modern surface warships of projects 22 350 and 20 385 being implemented?

Project 20 385 is in some way lagging behind, as for the frigates, as I have already commented, the frigate "Admiral Kasatonov" will soon become part of the Navy, the St. Andrew's flag will be raised on it (the frigate "Admiral Kasatonov" has already been accepted into the Navy on July 21, interview conducted a few days earlier).

One of the difficult questions for the Russian Navy in recent years is minesweepers. What is the overall situation with the 12,700 ships, have you managed to overcome all the difficulties associated with import substitution?

We have coped with import substitution in most of the positions, the plant has reached a very good calm rhythm, one minesweeper per year. But since the volume of the ordered equipment is decent, starting from 2021 we will reach the rhythm of production of two such ships a year, and the construction of the entire series will be completed soon. The most important thing is that we are not let down by our key suppliers who supply some types of marine equipment, and in particular these are diesel engines. But we know that the situation at the plant is improving every year, the Ministry of Industry controls everything that happens at the Zvezda plant, so I hope we will very soon forget about these problems as such.

How is the work on Admiral Nakhimov progressing and when will Peter the Great be upgraded?According to Admiral Nakhimov, the work is gradually entering its final stages and is proceeding according to the schedule.

How is the work on the air-independent (anaerobic) power plant going? How do you personally see the further development of the submarine fleet?

Let's all the same we get away from the boring term "air-independent installation", it is air-independent in the context that it can work under water and does not require oxygen, but with the same success, a nuclear reactor works under water and does not require oxygen. Here, probably, we are trying every time to come up with new terms in order to say about the main thing, that a submarine is good when it has the maximum possible autonomy for underwater navigation. From this point of view, there are at least five or six classical instruments that are used by various fleets of the world, and Russia is no exception in this sense. I think we will use each of these possible options in order to increase stealth, quietness and autonomy of our submarines. Therefore, probably

The so-called air-independent power plant works on the principle of fuel cells, and then the taste went on - someone likes hydrogen and oxygen on board, someone extracts it as needed, someone keeps it in tanks. As a matter of fact, in my opinion, fuel cells have been flying to space since 1968, so there is no need to say that this is some kind of super-duper innovation. Another thing is that in such capacities and in such volumes on submarines, it can be used for the first time.

But I repeat once again, given the diversity and variety of possible ways to solve this problem, using the technologies that exist in the Russian Federation, I would not focus on this specific solution to the problem, which is so much talked about all over the world.

- In 2019, the Project 12322 Mordovia landing ship was sent for repairs. How do you assess the need for such ships, and are you planning to resume their production in the future?For Russia, which lives, roughly speaking, in two seasons, winter and summer, hovercraft are a struggle for versatility, we walk on ice as well as on water and we can go on land. This is a good option for solving the amphibious properties of any transport platform, it seems to me that it is far from correct that we abandoned them, it remains to count them alive on one hand. While the adversary has such transport platforms, they are developing, they are making more of them, increasing the carrying capacity.

It seems to me that it would be nice for the Navy to return to understanding the placement of an order, especially since we have not lost the groundwork, the energy of these ships is also clear to us, so the most important thing is the order. There will be an order - we will definitely execute.

What is the current situation with COVID-19 at USC enterprises and in particular at Sevmash and Zvezdochka?The trouble and beauty of closed cities is how quickly this epidemic begins, so quickly this epidemic ends, because it is clear how to localize it, and today the situation is completely under control. The number of cases is decreasing, thank God. I am glad that the management of the enterprises treats the health of employees with awe. I am absolutely convinced that we have gained good experience to continue to deal with this kind of epidemiological difficulties. If you like, this is akin to a biological attack on a country. Maybe I'm talking too pompously, but we take it very seriously.

How did the pandemic affect USC in general, and will the SDO terms be postponed because of it?

Of course, we had difficulties, in some cases we had to create additional commissioning teams, somewhere to look for backup teams to complete certain works. Thank God, we coped, we do not see significant deviations, although of course we do not sew felt boots, we have a planning horizon for ten or more years, so from this point of view, I hope there will be no significant progress.

Two years ago I was at the Amur shipyard. They talked a lot about the implementation of the Compact Shipyard project. How do you feel about these ideas and how, in general, USC is working on optimizing production and, in particular, introducing lean technologies?

For the third year already, the plant has entered a normal rhythm of work, when we hand over one corvette a year and work on a civilian theme. Approximately one civilian and one military vessel is launched every year from the stocks of the Amur shipyard. I hope that we will maintain this rhythm, and I would very much like to see the systematic increase in production volumes and diversification continue to take place.

From the point of view of "compacting" the shipyard, we have completed the first stage, identified and fenced off everything that we will need for the functioning of this shipyard in full. The task for us is to ensure that the volume of production and the number of orders correspond to the development of the shipyard, because the plant was pretty much abandoned. Today, it has a couple of fundamental problems associated primarily with the fact that the region is equated to the regions of the Far North, and these costs are few who compensate. For example, our civil customers do not care why the cost of manufacturing a particular vessel in the Far East is higher than in the Northwest.

But on the other hand, the President clearly set the tasks for the development of shipbuilding in the Far East, so we are not going to get off our rails anywhere, and will continue to move forward.

Lean manufacturing or the USC production system did not receive its abbreviation while it lives under the name of the production system, but it has many interesting, powerful results. In particular, without investment for a year and a half, using the tools of the production system, we were able to increase the productivity of the Krasnoye Sormovo plant from seven dry cargo vessels to 11. Our next goal is to enter the production of 15 of the same dry cargo vessels, in order not only to show all the charms of the production system, but and once again prove that only the production of serial products is predictable both in price and in terms of delivery. ■