Andrei Martyanov's latest video pointed me to this article.

Russian microelectronics - not a myth, or big problems of small measurements

The head of the European Commission, Ursula von der Leyen, is very wrong. The Russian "Daggers" and "Calibers" have their own "smart head" on their shoulders

Vladimir Gundarov

November 17, 2022, 11:00am

With a difference of a week, two reputable American publications, The New York Times and The Washington Post, published materials written as if under a carbon copy, in which they revealed Le secret de Polichinelle: Russian communications equipment and remnants of cruise missiles, such as laser rangefinders and radar homing heads found in Ukraine, use American microelectronics. At the same time, the markings on the two chips showed that they were manufactured back in 2019.

Damien Splitters, Deputy Director of Operations at Conflict Armament Research (CAR), a British research organization that tracks the supply of conventional weapons, ammunition and related military materials to conflict - affected areas, told the publication. "Modern Russian weapons and communications systems were built on the basis of Western chips," Damien Splitters pointedly stated.

Is this true or fictional? We'll figure it out.

From women's diseases to high technologies

"President of All Europe" Ursula von der Leyen, speaking to the European Parliament, said:: "The Russian army is taking chips out of dishwashers and refrigerators to fix military equipment. They don't have semiconductors anymore. Russian industry is torn to shreds!"

"Only two notorious "intellectuals" could believe this fake about chips-Ellochka Shchukina and Liz Truss. In fact, I suspect that von der Leyen herself didn't understand what she was saying. Because, as it was established, in the Russian semi-automatic washing machine "Fairy" the most difficult device was the XZK-B timer for switching washing modes. Maybe I took the wrong car apart in search of military chips?.."

For understanding. A microchip is hundreds, thousands, or even millions of semiconductors placed on a quartz wafer. The more semiconductors there are, the more operations the microchip performs per unit of time. Its physical size also matters. The smaller it is, the better and, accordingly, more expensive. In fact, it is the brain of integrated circuits, which are divided into categories.

And in Russia, these categories have a boring, meaningless name - "Acceptance", provided with numbers from 1 to 9. The last two mean the highest category of chips that are designed for rocket and space technology and nuclear weapons. In the West, they correspond to the categories of commercial, industrial, military and space. The sale of the last two categories of chips to Russia was carried out only with the permission of the US Department of Commerce, which oversees export control, and only in exceptional cases when they were needed, for example, for spacecraft flying to the ISS, or for creating spacecraft and other space equipment in cooperation with other space agencies within the framework of international programs..

"And here is what is remarkable: there was a suspicion that the Russian automatic interplanetary station "Phobos-Grunt" could not rise to the calculated orbit precisely because it was created using American microchips of the military category, and the space category was required. In other words, not every chip is equally suitable for both a washing machine and a cruise missile. "Caliber", assembled from parts from the "washing machine", will not fly, and a washing machine with microchips from target designation and guidance systems will cost like a rocket. It would seem that this is quite understandable even for a gynecologist in his main specialty. But, apparently, not everything is so simple."

There are other suggestions about the fake about chips from washing machines - most likely, von der Leyen wanted to humiliate Russia on purpose, and it is possible that her assistants who prepare her "cheat sheets" simply do not have information about the state of Russian microelectronics.

Although the domestic microelectronics industry has recently really experienced not the best of times. In Stavropol, at the Signal radio factory, where they make electronic warfare systems and complexes for combat aircraft, including the famous Khibiny ,I happened to see a box full of foreign-marked chips on the assembly table. By the way, the stamp "FSB of the Russian Federation" on printed circuit boards, no matter how I looked at it, I didn't see it. Although the photos of printed circuit boards allegedly extracted from the Russian X-101 cruise missile, which have bypassed the Western media, have such a stamp, they say.

"Where did it come from? Maybe it was completed with a retoucher?.. When asked about checking imported chips by the FSB special service for hidden "bookmarks", the company's specialists could not answer: it seems that imported chips are checked, but they don't know where and by whom. So the stamp "FSB of the Russian Federation" in the photos in the Western media is another fake, this time drawn, most likely, by the needlewomen of the so-called Center for Countering Disinformation, subordinate to the National Security Service of Ukraine, or by specialists of the East StratCom Task Force of the European External Action Service of the European Union. In terms of creating fakes, these organizations are worth each other."

As for the use of imported components in Russian equipment, this information has never been hidden: yes, we use not only chips, but also many other, more "dimensional" equipment. Thus, according to the Government of the Russian Federation, in 2019, in the structure of the cost of ship components for military shipbuilding, the cost of foreign components reached 60%. In other words, the Navy in the modern shape of the ship's composition, even taking into account the price difference between domestic and imported components, was still about half domestic. Probably not yet.

Needless to say, the former Russian government placed too much faith in the international division of labor and industrial cooperation. As it now turns out, shortsighted. Therefore, now there is nothing left but to learn from your own mistakes and remember the well-forgotten old ones.

This is how Oboronprom survived

And we have something to remember. For example, the world's first heavy drone was originally ours. Back in 1939, Ruben Chachikyan, who later became the chief designer of the Moscow Instrument Design Bureau Voskhod (the future JSC Aeropribor-Voskhod), developed an automatic control system for TB-3 and SB bombers, which performed the entire flight-from takeoff to landing inclusive - without a crew. Moreover, at the beginning of the Great Patriotic War, the TB-3 unmanned bomber with the Chachikyan system was tested in a combat situation. Unfortunately, it didn't go any further - the war prevented it.

"In the era of the creation of the space rocket and nuclear shield, we were in the" thin " field of knowledge, technology and technology, which is microelectronics, if not ahead of, then kept up with developed industrial countries. In the 1970s and early 1980s, the USSR ranked second after the United States in terms of sales of microelectronic products."

However, all developments were aimed at servicing only one department - the military. And when the defense order began to decline rapidly, and the state did not have enough money to convert production, all enterprises that worked for defense turned out to be lame ducks.

That's when the import "strangled" the domestic manufacturer. This happened, for example, with the microelectronics workshop of the Scientific and Production Association of Measuring Equipment (NPO IT) in the city of Korolev near Moscow.

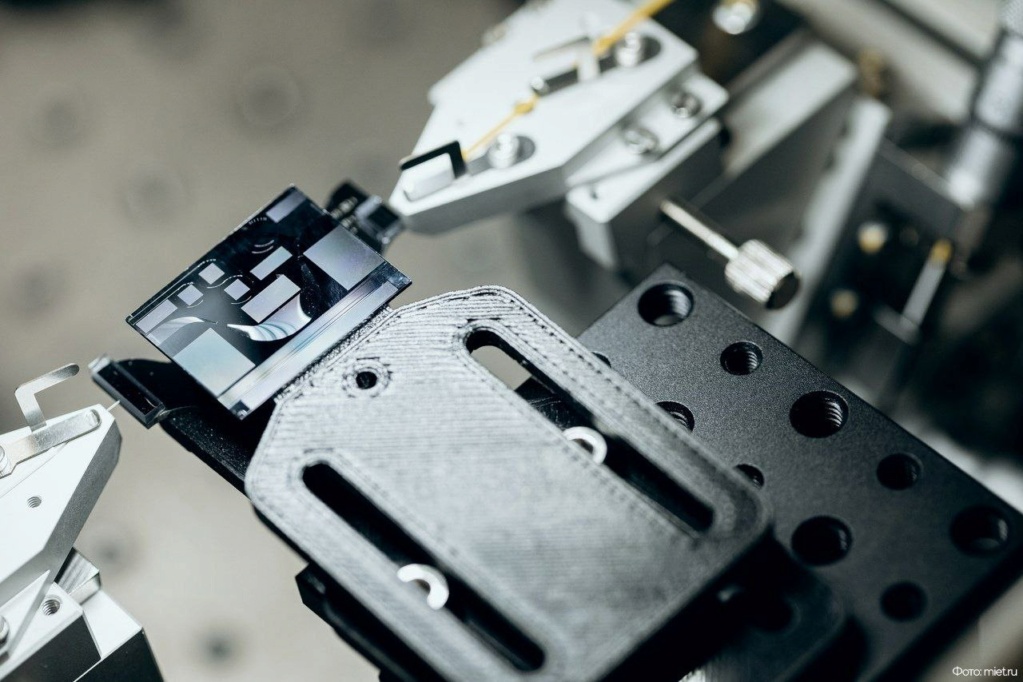

The NPO made onboard computing systems, antenna complexes, systems for operational processing of telemetry information, and numerous sensor-converting equipment for space rockets. Ten years ago, I was able to visit the microelectronics shop of an NGO and see with my own eyes how they create chips for space technology. And the company's management did not hide the alarm: the products were manufactured using the technologies of the 70s of the last century, and no one gave money for updating and developing production, and the customer was in the singular - Roscosmos. And how many chips are required to launch a single space rocket? A maximum of a dozen, so the production of microchips became literally piece-by-piece, and it was necessary to feed a large team. So calculate what the cost price was.

"And there was also competition within the rocket and space industry. The three space rocket companies accounted for 12 companies developing space-class chips. The result is quite natural: the most resourceful survived. And the attempts of NGO IT to "integrate" into the projects of the gas production industry ended in nothing. Now, according to Igor Davydov, chief designer for diversification and new types of products, a small section of the microelectronics workshop remains in the NGO, where only two people work. No demand - no supply, this is the law of the market.

"

Here's another example. The Research Institute of Thermal Power Instrumentation with the participation of Aeropribor-Voskhod JSC has made an experimental sample of an on-board laser airspeed meter (LIVS), which could be useful for civil aircraft. "If an order is received for a baroinertial system, we will definitely make it, do not doubt it, "Vyacheslav Dyatlov, First Deputy Chief Designer of Aeropribor - Voskhod JSC, told me last spring. Although customers did not appear a year ago, now the company operates smoothly - it makes air signal systems for Tu-160, Tu-95, Tu-22 strategic bombers and for the most modern cruise missiles "Burevestnik" and "Caliber". And how will they load production when the volume of state defense orders is reduced?

This is another sensitive issue. Patented inventions turn into innovations when they become commercial projects that bring profit to the patentee. In Russia, a lot of inventions are made, but not every invention becomes an innovation.

"But be that as it may, the allocation of three trillion rubles for the technical re-equipment of defense plants within the framework of the Federal Target Program for the Development of the Defense Industry for 2011-2020 made it possible to purchase and install modern processing complexes made in Germany, Sweden, South Korea, and Japan in a short time. With such equipment, you can start diversification and import substitution right now."

We are ours, we will build a new chip

Almost from the very beginning, it was clear that cooperation with the West in the field of high technologies has pitfalls. And in 2015, for the first time in history, the Ministry of Industry and Trade of the Russian Federation approved the Regulation "On the procedure for using the electronic component base of foreign production to ensure the development, modernization and production of weapons, military and special equipment". The document was put into effect by the minutes of the meeting of the Board of the Military-Industrial Commission of the Russian Federation. The Head of the Department of Military Missions of the Ministry of Defense of the Russian Federation brought it to his subordinates as a guidance document.

"Every year, the Ministry of Industry and Trade and the Ministry of Defense issue multi-volume "Intersectoral Restrictive Lists", which list electrical and radio products allowed for use in weapons and military equipment, including integrated circuits, optoelectronic devices and quantum electronics products. As a result, now it is no longer permissible to use any imported microchip in domestic weapons and military equipment, but only the one that is included in the annually adjusted "Intersectoral Restrictive List"."

In general, the program of import substitution in microelectronics is creaking, but it is being implemented. Domestic analogs of integrated circuits corresponding to the level of American ones produced in the last decade have appeared. This is a good indicator, considering that the return on investment in the production of microelectronics begins in 5-10 years.

But it can also be faster. The multi-profile Russian IT company Sitronics Group has been producing chips with a size of 90 nm since 2012, and last year it started mass production of chips with a size of 60 nm. In 2016, the Russian Angstrom-T plant was put into operation, where the production of modern integrated circuits was resumed. The production capacity of the enterprise is 180 thousand products per year.

The Micron Group of Companies is called the largest Russian manufacturer and exporter of microelectronics. According to information published on its official website, the group's share in the export of Russian electronics is 54%. JSC "Micron" produces over 4 billion microchips annually. The list of major domestic IT companies also includes the Moscow Center for SPARC Technologies, Baikal Electronics JSC and a dozen other enterprises and organizations. As the military says (and these are the main consumers), the personnel is assembled. The offensive plan has been developed and approved.

"The industry plan, as follows from the" Strategy for the Development of the Electronic Industry of the Russian Federation for the period up to 2030", approved by the order of the Government of the Russian Federation in January 2020, provides for the development and industrial development of silicon technologies for the production of electronic components with topological standards of 65-45 nm, 28 nm, 14-12 nm, and even 7-5 nm. At the same time, microchips with a topological norm of 5 nm are going to be made first at foreign sites, but with the subsequent transfer of production to Russia. From this it follows that chips over 5 nm will be made in our country without contacting foreign manufacturers."

A separate line in the "Strategy" describes the problem of heterogeneous integration of indium phosphide with silicon and the creation of complex semiconductors based on them for photonic integrated circuits. This implies a revolution in integrated circuit technology, which is expected to have a huge impact on the production of military, civil and dual-use microelectronics products. In solving this problem, we are moving almost in parallel with the Microsystems Technology Office of the US Department of Defense's Advanced Research Projects Agency (DARPA).

Thus, the 13th President of the European Commission was deeply mistaken when she said that " Russian industry is torn to shreds." Perhaps this was the case when our industry was supervised by American advisers. But today everything is different: thanks to hardworking and talented people, Russia is returning to the high-tech mainstream. As one intelligent person said, you can change everything, but you can't change the people. So we have everything ahead of us. ■

https://translated.turbopages.org/proxy_u/ru-en.en.6c2b0ef9-6379b645-c245ff88-74722d776562/https/zvezdaweekly.ru/news/20221114160-AVHfx.html

sepheronx

sepheronx