For many years, the BTR family of APCs (BTR-40, BTR- 152, and BTR-60/70/80) and BRDM-1/2 amphibious armored patrol cars were the main Soviet and Russian offering in the market for wheeled armored vehicles. They had many advantages, including simplicity and low price – but by the early 1990s it had become clear that they no longer met modern requirements. Besides, following the break-up of the Soviet Union, the market was flooded by the surplus hardware being sold off by the newly-independent former Soviet states. A few years later, Ukraine began to offer refurbishment and upgrade options for the BTR-80, before launching production of its own version of that APC. The Ukrainians then developed the BTR-4, a next-generation APC of their own design, although the vehicle was plagued by poor manufacturing quality.

Meanwhile, the conflicts in Afghanistan (2001) and Iraq (2003) highlighted a pressing need for next-generation wheeled armor, forcing the West – the United States included – to place large and urgent orders for various mine-resistant (MRAP) vehicles, from the relatively light Iveco LMV to the heavy Oshkosh M-ATV. Their use in the field was deemed an overall success, spurring demand for such vehicles all over the world. In addition to purchasing finished hardware, some states launched local production programs under foreign license. For example, the Barys and Alan MRAP vehicles assembled in Kazakhstan were developed by South Africa’s Paramount Group.

In Russia, the MRAP niche had for various reasons remained vacant for a very long time. Russian companies had developed such 4x4 vehicles as the GAZ-3937 Vodnik and the VPK-23114 Tigr-M, but they did not offer a sufficient level of protection and carrying capacity. The new BTR-90 APC never reached mass production. The VPK-7829 Bumerang standard wheeled platform is essentially a wheeled infantry fighting vehicle and has yet to complete trials. There are also various armored vehicles built on KAMAZ and URAL chassis, but they were not specially designed as MRAP hardware and their mine resistance is inadequate.

As a result, the Russian Army’s first proper MRAP vehicle was the Rys, a version of Italy’s Iveco 65E19WM assembled in Russia from Italian components. A total of 358 vehicles were delivered before cooperation with the Italians ceased after Russia’s annexation of Crimea in 2014.

There are no foreign MRAP vehicles being built in Russia at this time, but several indigenous Russian MRAP programs were nearing completion by the time the assembly of Iveco vehicles ground to a halt. There are only two Russian companies that have active programs in this field: the Ural Auto Plant, and Remdizel. The latter has already launched mass production of several families of such vehicles, and there are several versions within each family.

The first to enter mass production was the K-63968 Typhoon-K, a 6x6 modular armored vehicle. Its development began in 2011, and tests of the first mobile prototypes commenced the following year. The MoD placed the first contract for 40 such vehicles in early 2013; another contract for over 100 vehicles followed before the year’s end. The Russian forces have used these vehicles for several years in Syria; to the best of our knowledge, there have been no export contracts.

Almost simultaneously with the K-63968, Remdizel launched the K-63969 Typhoon-K model, which is a 6x6 wheeled, solid-body armored vehicle that offers the best level of protection of all Remdizel and other Russian MRAP models. There have been no open-source reports of any domestic or export contracts for these vehicles, but we are aware of interest expressed by some of the Russian MoD branches.

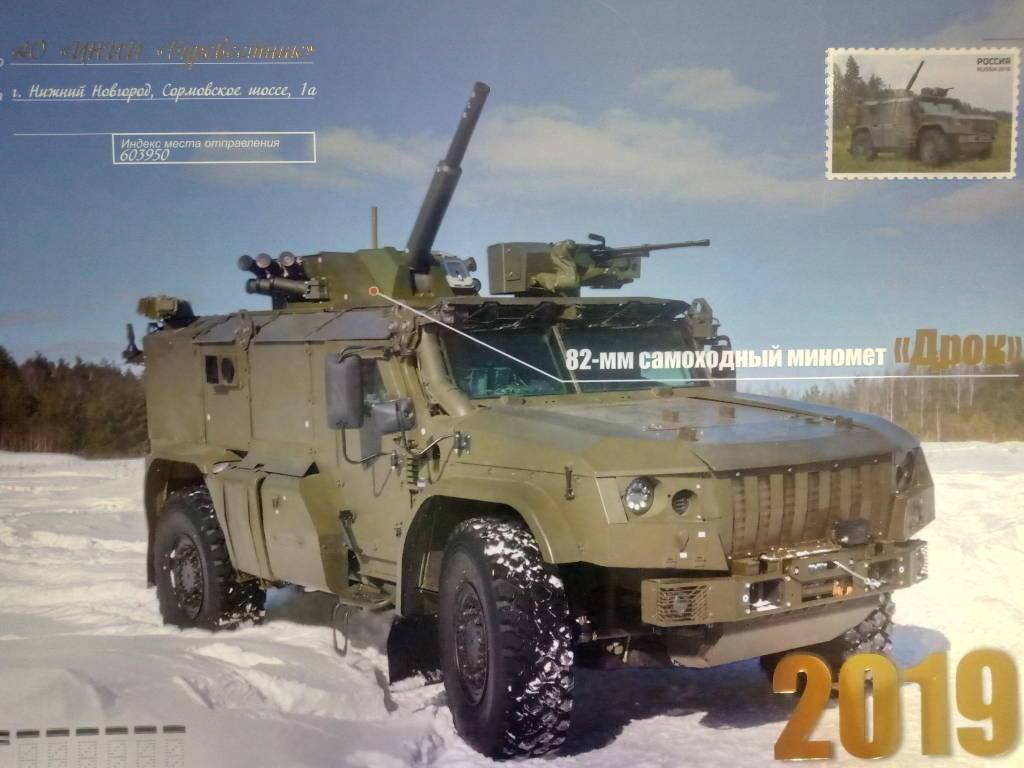

There is also the K-4386 Typhoon-VDV (Rosomakha), a 4x4 frameless wheeled one-box armored vehicle, which has yet to enter mass production. The first prototype batch of these vehicles is expected to complete trials later this year. The K-4386 chassis may be used for a whole range of special vehicles, such as the 2S41 Drok self-propelled 82mm mortar (the Nabrosok-Drok-KSh R&D program) and the Typhoon-PVO personnel carriers for Igla and Verba MANPAD crews (early prototypes were unveiled in May 2019).

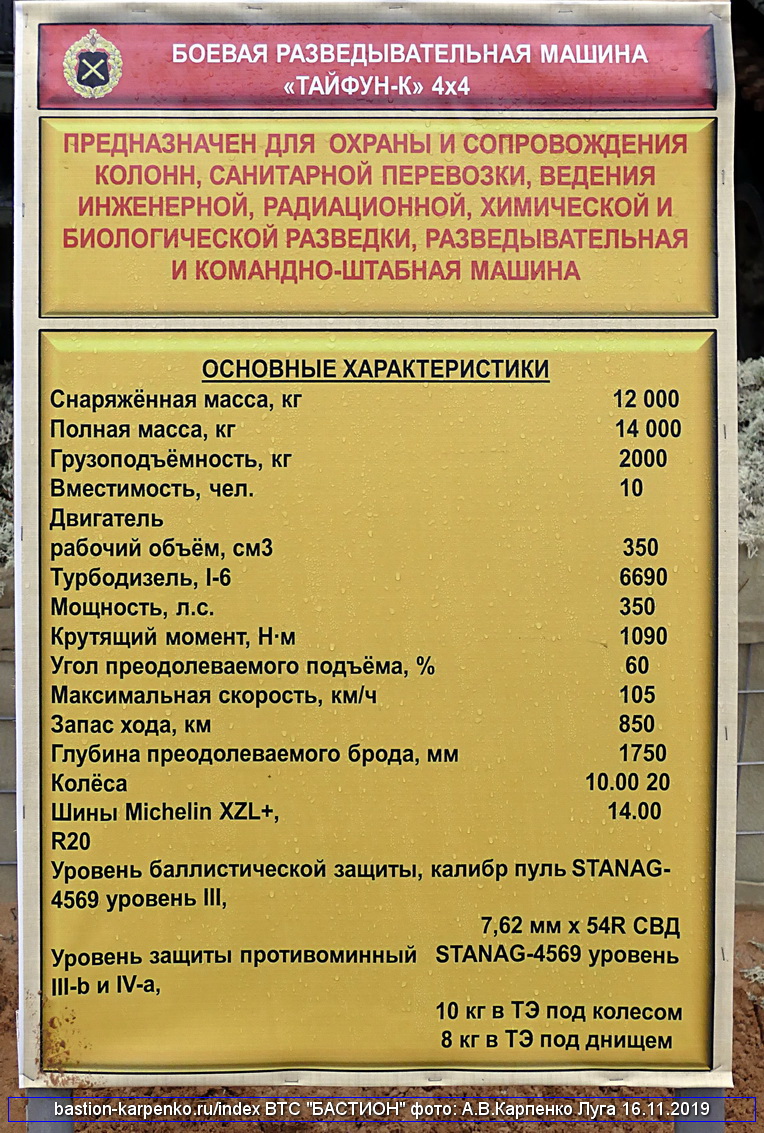

Finally, there is the K-53949 Typhoon-K, a 4x4 vehicle that will probably become the main Russian MRAP model. Despite its lower curb weight, it offers the same level of protection as the heavier K-63968.

The first prototype of that vehicle was designed at the company’s own initiative in 2015. The model has already completed preliminary trials at Remdizel. Substantial changes have been made to the early design: the first three prototypes were equipped with a hydropneumatic suspension and an automatic gearbox, but it was then decided to revert to a spring suspension and a mechanical gearbox.

In late 2017, the MoD took delivery of the first 10 mass-produced vehicles. In August 2018, it signed a contract for another 59.

Even though deliveries of MRAP vehicles to the Russian forces commenced only recently, they have already seen real combat. At least one unit of the K-53949 Typhoon-K and one K-4386 Typhoon-VDV were deployed to Syria in 2018. Both were spotted in that country in February.1 The K-53949 is equipped with an RP-377VM1 electronic jamming system.2 It was seen near Douma (Eastern Ghouta) immediately after the city’s recapture by the Syrian Army. The vehicle was probably one of the 10 K-53949s delivered to the Russian forces in December 2017. The K-4386 Typhoon-VDV, which has yet to complete trials, was spotted in the Tartus area, probably as part of its trials program with the Russian forces. It was the only new-generation Russian MRAP vehicle in Syria equipped with a 30mm gun.3

The K-53949 design is also used in the AS-Linza tactical-tier medical vehicle. The vehicle’s curb weight is 15 tonnes, and it offers the same level of protection as the K-63968. It is equipped with a Class 1 or Class 2 medical bay. The first prototype was assembled in 2017, and the first Russian MoD contract for 27 vehicles was signed in 2018, for delivery in 2018-2020.

In 2018, the K-53949 chassis was also used to develop a new platform for the Kornet-D anti-tank missile system, equipped with eight guided missiles. Previously, that system was mounted on VPK-233116 Tigr-M chassis.4 Shortly before that, it was reported that the same chassis was used to develop the Strela tank-fire control vehicle.5

The K-53949 was the first Russian MRAP vehicle delivered to foreign customers. In 2016, Remdizel signed a K-53949 promotion agreement with the Russian arms export intermediary Rosoboronexport. In 2017, the vehicle was demonstrated at the IDEX 2017 arms expo in the UAE. The first export delivery was made to Uzbekistan in May 2019.6 As far as we can tell, some of the assembly operations are handled in Uzbekistan itself, which is a new development for Russian army hardware exports. Based on that information, we can also surmise that the Uzbek contract is for at least several dozen vehicles.

To summarize, it is safe to assert that the Russian school of MRAP vehicles design has come into its own. Several models have entered mass production and even seen real combat. As a result, some of them have already won foreign customers as we are aware of at least one export contract for the K-53949. Given the healthy global demand for 4x4 wheeled MRAP vehicles, more export contracts are sure to follow.

https://twitter.com/vezhlivo/status/986541920544612352

https://twitter.com/AndreZykov/status/986224314847506432

For more details, see: Frolov A. New Russian MRAP Vehicles in Syria // Moscow Defense Brief, 2018, #3

https://bmpd.livejournal.com/3312525.html.

https://bmpd.livejournal.com/2822210.html.

https://dambiev.livejournal.com/1601810.html

Isos

Isos