IntroductionIn the 1990-2000s, a dramatic situation developed in the domestic helicopter engine building, due to the fact that after the collapse of the USSR, Russia remained without serial production of helicopter engines, in particular, the main aircraft engine of the TV3-117 family, which was manufactured by Zaporizhzhya Motor Sich enterprise. In addition, for a long time, new domestic helicopter engines were not developed or commissioned. Some projects have been started, but have not been completed, for example, the RD-600 helicopter aircraft engine.

The lack of domestic aircraft engines led to the fact that almost all domestic developed and modified helicopters were used aircraft engines of foreign production. Helicopters Ka-226, Ka-226T, Ansat, Ansat-U, Ka-62, Mi-26 use foreign-made engines. Now we are considering the option of using a foreign engine on a promising medium-sized transport helicopter. Moreover, even on the Mi-38 medium-capacity helicopter, the installation of a foreign engine was originally planned, and only the supplier's refusal to supply engines to Russia forced domestic developers to create a Russian engine (TV7-117V). Today, after many years of discussion, the issue of developing the serial production of VK-2500 engines in Russia has been resolved.

What is done by the "United Engine-Building Corporation"Since the beginning of this decade, the program of import substitution in helicopter engine construction was launched, within which a very significant amount of work was carried out. The main results can be considered the development of the serial production of the VK-2500 family engines in Russia. In addition to assembling the engines of the basic version entirely from domestic components, work was carried out to create deeply upgraded VK-2500P / PS engines, in particular, VK-2500PС-03 certified for the newest Mi-171A2 helicopter. The VK-2500PS engine is a modification of the VK-2500 engine with a new fully digital control system of the FADEC type. Now the state joint testing of another modification of the VK-2500 VK-2500P engine for the modernized Mi-28NM helicopter, which is in the stage of flight tests, is on the agenda now.

In addition, the helicopter engine TV7-117V for Mi-38 has been certified. The basic version was developed in the 1980s, but the engine was certified quite recently, the Certificate was obtained with certain limitations of the operational range. During 2018, the whole range of measures to expand the operational range within the framework of the Terms of Reference should be completed, Fokin added.

We consider the possibility of developing a PD-12V engine for perspective heavy helicopters and VK-800V for light helicopters. So on the basis of the gas generator of the dual-path engine PD-14, intended for the passenger-oriented MS-21 airplane, the PD-12V engine for heavy Mi-26 helicopters is being developed. As for VK-800, work is now under way on an aircraft engine version intended for use in the power unit of the L-410 aircraft. At the same time, the CIAM supports the resumption of work on the creation of a helicopter version of VK-800V.

Finally, work was started to shape the perspective helicopter engine. At present, the company "ODK-Klimov" forms proposals for a prospective engine under the "Prospective engine for helicopters" program, this project has not yet been examined by CIAM. But so far it is known that an aircraft engine will be offered in a larger class of power than TV7-117V, which exceeds the existing analogues in terms of manufacturability and specific mass.

Creation of advanced scientific and technical reserveCreation of perspective aircraft engines is impossible without creation of advanced scientific and technical reserve (NTZ). The goals and programs of NTZ development are already defined. In accordance with the adopted program, prospective aircraft engines should have significantly better characteristics in comparison, for example,

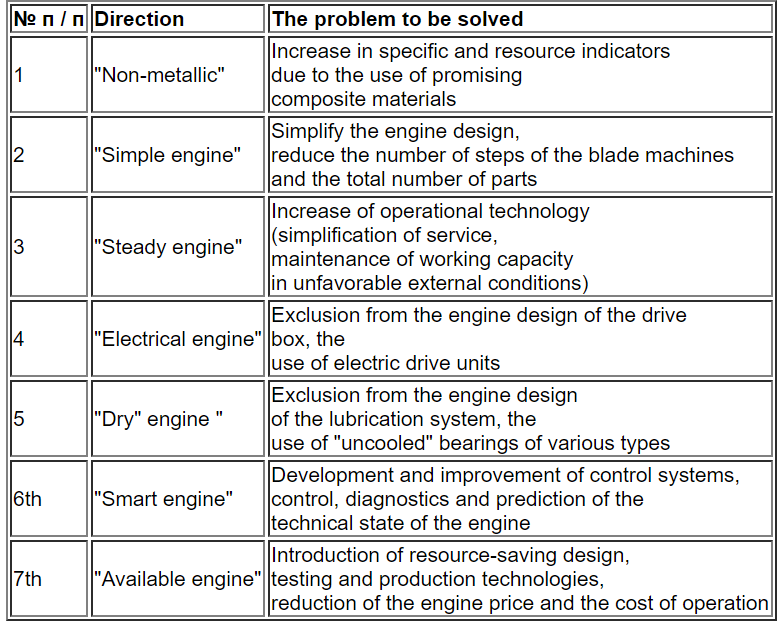

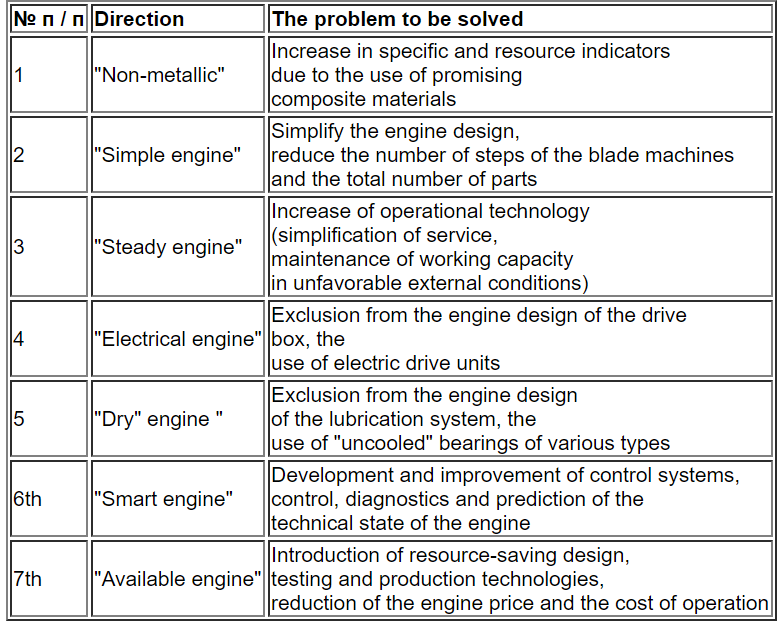

The main directions of the development of helicopter aircraft engines The specialists of CIAM developed seven main directions for the development of aircraft engines for prospective domestic helicopters

Also the task is to improve the methods of 3D-design.

To ensure these directions of work, the CIAM is developing a whole range of breakthrough technologies. Together with the enterprises of the branch, the institute implements a program called "Development of Technologies for Advanced MGTS and AAP", the aim of this program is the creation of eleven demonstrators of advanced technologies.

Demonstration "electric" MGTD;

1 High-speed reducer MGTD;

2 Nozzle apparatus turbine from KM;

3 Heat exchanger for MGTD "complex" cycle;

4 Combustion chamber MGTD with elements from CM;

5 Experimental single-stage pulp and paper mill

6 Experimental two-stage PPM;

7 High-speed stage of helicopter gearbox.

8 Demonstration turbo-compound aviation piston engine;

9 Demonstration MGTD on gas supports;

10 Demonstration rotary-piston engine.

In accordance with the program, in 2017, the planned design studies with conditional leveling for 2025 and 2035 technologies were performed, and in 2018-2019 it is planned to manufacture and test demonstrators.

To achieve the stated progress of the characteristics of helicopter engines, the CIAM defines a set of technologies that allow obtaining products of a given level of perfection. So to "Technologies 2025" are:1 Two-stage pulp and paper mill;

2 Compact low-emission CS;

3 RK turbine type "Bliss";

4 Impeller of pulp and paper mill from KM;

5 Compressor casing from CM Cabinet of CS from CM;

6 KS Flare pipe from KM;

7 CA turbine from CM;

8 Hybrid bearings;

9 Electric drive of units;

10 Wireless sensors ACS;

11 HIPCs with remote access;

12 MGTD "complex" cycle with maintenance.

"Technology 2035" includes:1 Uncooled RK turbines from KM;

2 Case details in MS from KM;

3 Uncooled oil supports;

4 Shafts from CM.

Rodion_Romanovic

Rodion_Romanovic