Aircraft project "Baikal" (LMS-901)

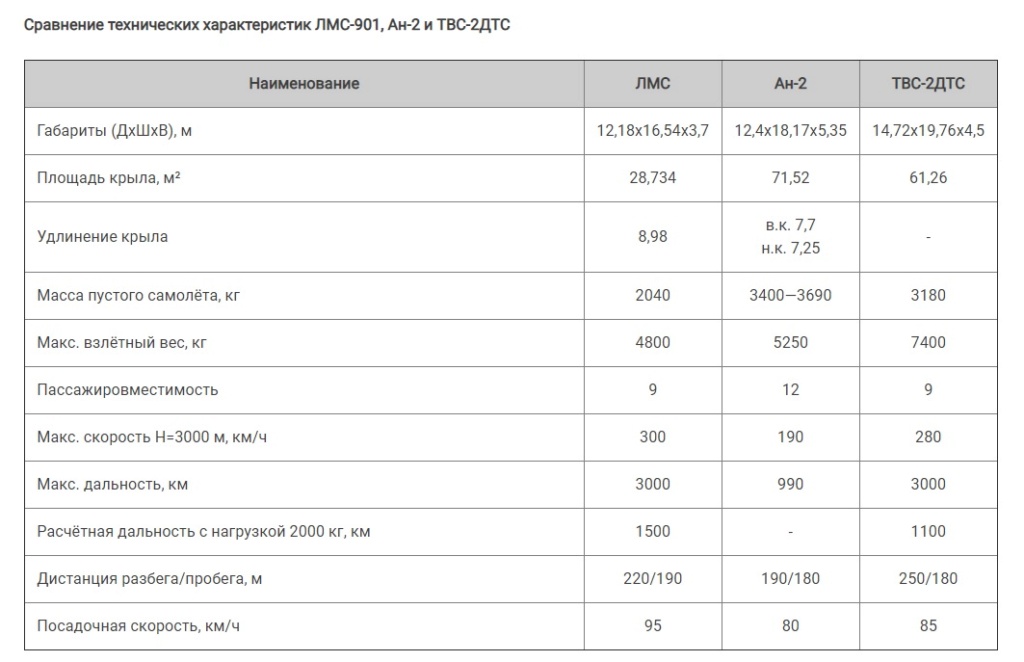

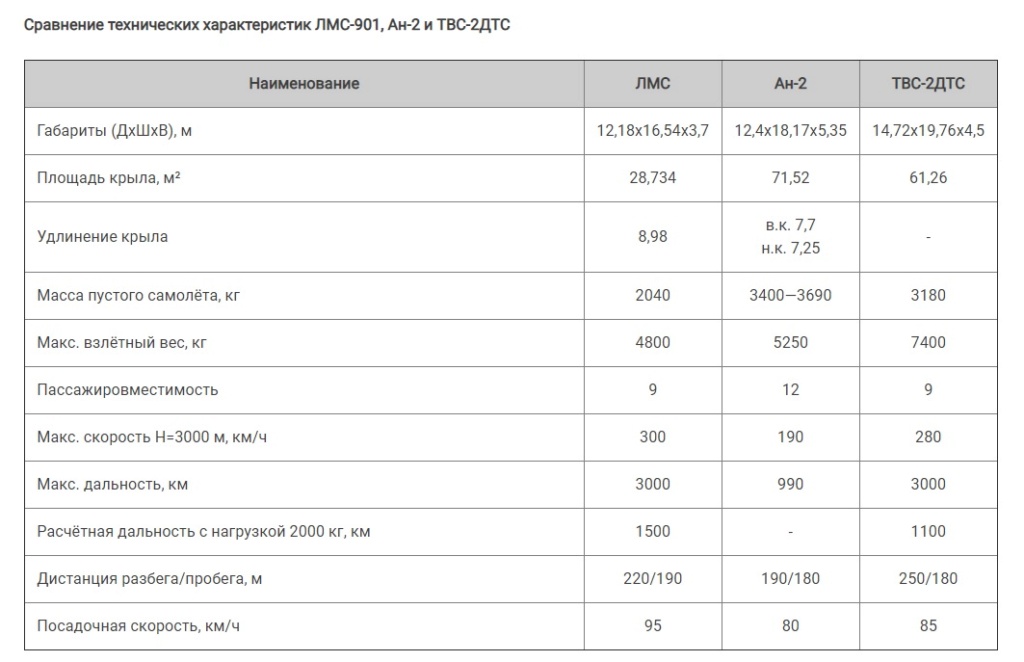

The web resource "Aviation of Russia" published the material of Andrey Velichko "Airplane" Baikal ", aka LMS-901. What is known about it ", which says that in the summer of 2019, the Ministry of Industry and Trade of Russia announced a competition for the development of a light multi-functional aircraft for nine passengers, abandoning the all-composite TVS-2DTS, which is almost ready for serial production, developed at the Siberian Research Institute of Aviation named after Chaplygin. Baikal Engineering LLC, a subsidiary of the Ural Civil Aviation Plant, was announced the winner of the competition.

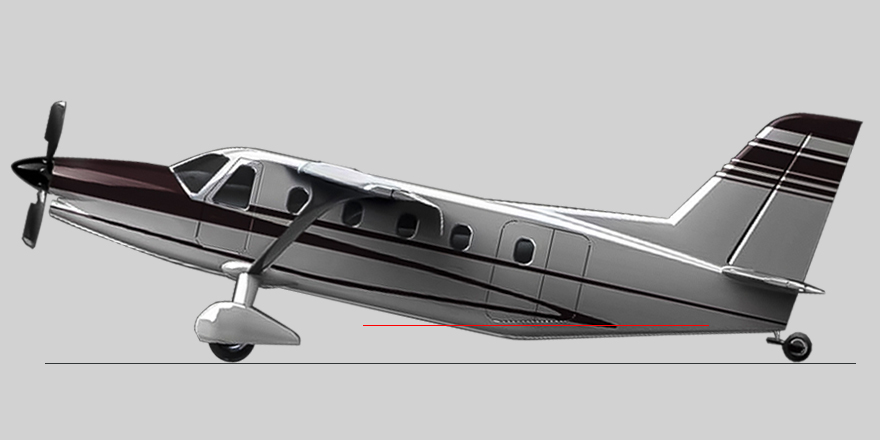

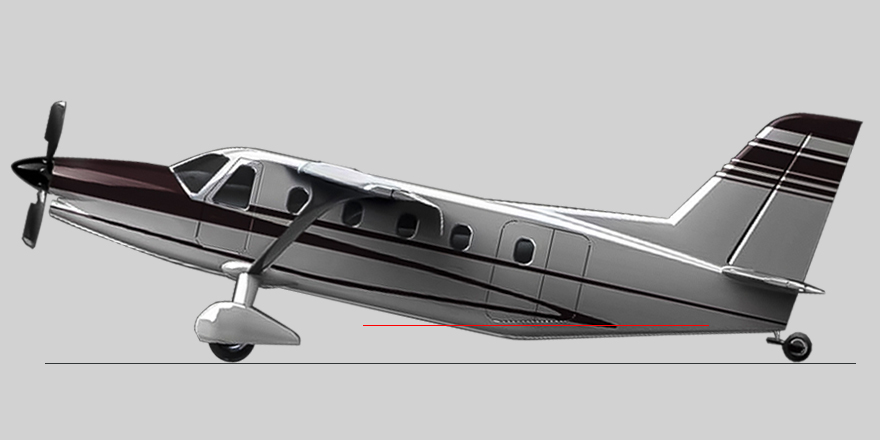

Design look of the light multifunctional turboprop aircraft LMS-901 ("Baikal") developed by LLC "Baikal Engineering" (a subsidiary of JSC "Ural Civil Aviation Plant" (c) aviation21.ru

Design look of the light multifunctional turboprop aircraft LMS-901 ("Baikal") developed by LLC "Baikal Engineering" (a subsidiary of JSC "Ural Civil Aviation Plant" (c) aviation21.ruAccording to the terms of the contract concluded with the winner of the competition, the developer must by the end of 2020 submit for static tests the first prototype of the LMS-901 (Baikal) aircraft, which will be held at the MAI. A year later - to perform the first flight and start flight tests. 2020 is drawing to a close. Let's see what we know about this aircraft and put all the known facts together.

In the article "What will be and when the plane" Baikal "will fly" last year, the reasons for abandoning TVS-2DTS were already considered. One of them was the use of an imported Honeywell TPE331-12UAN engine and a propeller manufactured by Hartzell Propeller Inc. as a power plant. (USA). But now it turns out that this was not the main thing.

As the chief designer of UZGA for aircraft construction Vadim Demin said in an interview with the AviaPort publication, at the first stage, a General Electric H80-200 engine will be installed on the LMS-901, this is an updated Czech-made Walter M601. The same is installed on the L-410, the LMS-901 will receive a modification for single-engine aircraft. In the future, the imported engine should be replaced with the domestic VK-800.

Also, at the first stage, imported avionics of the Garmin or Honeywell type will be used, followed by replacement with Russian equipment, and the same Hartzell propeller.

"The Hartzell propeller, four-bladed, 2.6 meters in diameter. It has a European certificate, but the certificate has not been validated in Russia. Preliminary negotiations have already been held with Hartzell, and I do not see any problems with its validation in Russia," Vadim Demin said. He added that at the second stage, it is planned to install a domestic propeller.

Thus, we can say that TVS-2DTS did not suit the Ministry of Industry and Trade, not only because of imported components and assemblies. This one-piece composite aircraft turned out to be excessively heavy and had to be made from foreign composite materials.

The empty weight of TVS-2DTS is 3180 kg, the maximum take-off weight is 7400 kg. An empty LMS-901 weighs 1980-2040 kg, and the maximum take-off weight is 4800 kg.

The aerodynamic design "biplane" has an excess wing area for the fixed size and weight of the LMS-901, so a strut-braced high-wing design was adopted for the new aircraft. The use of a streamlined strut allows you to get rid of the center section and optimize the weight of the aircraft. Its estimated weight will be 2.4 times less than that of the TVS-2DTS biplane, and accordingly, the labor intensity and manufacturing cost will decrease significantly.

The new aircraft will be operated at air temperatures from -55 to +50 degrees with the expectation of hangar-free storage, therefore, it was decided to use aluminum alloys as the main material. The use of composite materials is limited to non-power units, these are fairings, doors, hoods, fairings and wing mechanization.

In accordance with the TK, the takeoff and landing characteristics of the LMS should be no worse than that of the An-2. Due to the fact that the aircraft is smaller, lighter and has a higher aerodynamic quality than the An-2, the speed at an altitude of 3000 meters at maximum continuous operation of the engine will be 300 km / h.

According to the current aviation regulations, a single-engine aircraft cannot carry more than nine people, unless it is search and rescue, air forestry or parachutist drops. The task of meeting the requirements of the TZ is solved by minimizing the mass of an empty aircraft, which is almost 1400 kg less for the LMS-901 than for the An-2. At the same time, with the same load as the An-2, the aircraft has a normal take-off weight of 3700 kg, with which it can easily take off from a distance of 200-220 meters.

The aircraft will mainly be operated on unpaved airfields, therefore, the requirements for soil strength are the same as for the An-2. In the basic version with 720 mm wheels, the LMS-901 can be operated on unpaved runways with a bearing capacity of 4 kg per square centimeter. With 880 mm wheels, soil strength can be at least 3.5 kg / cm². The chassis for the LMS-901 will be supplied by NJSC Gidromash. The slightly higher landing speed compared to the An-2, as indicated by the LMS-901 developers, was selected from the condition of ensuring the possibility of landing with a large crosswind due to the increased wing load. At the same time, a significant power-to-weight ratio and the presence of a reverse of the propeller make it possible to have a take-off / run distance close to the An-2.

The landing gear of the aircraft is tricycle, non-retractable, made according to the scheme with a tail support. The main advantage of such a chassis is the ability to take off / land from poorly prepared airfields. To improve stability characteristics when performing a take-off run and a run with a raised tail wheel, it is planned to install a system for stabilizing exchange rate stability using differential braking.

Two options for the design of the main landing gear are considered.

Pneumohydraulic, telescopic, fixed at the ends of the transverse beam installed in the lower part of the fuselage.

Lever - a beam with an external shock absorber located inside the fuselage.

The tail support is pneumohydraulic, made according to a semi-link scheme. For free orientation of the tail wheel when moving on the ground in the process of taxiing by its own power or towing by ground means, the rack has the ability to turn 360 degrees. The tail wheel with dimensions 400x150 mm is a low pressure pneumatic.

Another difference from the An-2 is the location of the entrance door - it is located in the aft fuselage, where the floor is oriented in the same plane to the ground in the parking lot and at an angle in flight. According to the developers, it will be more convenient for passengers - when entering, they get on a flat horizontal floor, and then they move up the cabin to their places. Also, this arrangement allows for mechanized loading.

The height of the LMS-901 cabin - 160 cm - is the same as that of the L-410, it is almost 20 cm less than in the An-2. Considering the average height of an adult, the size of the aircraft, the layout of the cabin and the slope of the floor of the cockpit in the parking lot, it cannot be said that it will be convenient to make your way to your seat. The main variant of the cabin layout is passenger, with nine seats - four along the left side, five along the right side.

From the point of view of the safety of a single-engine aircraft, there are restrictions established by the Federal Aviation Regulations FAP-128, which oblige the pilot of a single-engine aircraft to build a route in such a way as to be able to make an emergency landing in case of engine failure. This means that with an altitude of 3000 m and an aerodynamic quality of 15, there should be landing sites along the entire route within 45 kilometers. To get around these restrictions, UZGA plans to use a hybrid power plant.

As Vadim Demin said, options are being considered for placing an additional power plant (DSU) - two small-sized electric motors with folding propellers on the wing consoles or installing an electric motor on a free turbine under the hood so that, in the event of a main engine failure, rotate the free turbine together with the propeller.

Two 100 kW electric motors of a DSU and 200 kilogram rechargeable batteries make it possible to fly for about 45 minutes. For an electric motor integrated into a motor, it will be necessary to carry out a full test cycle.

“In my understanding, the installation of“ flying ”engines on the wing, until they open and work, does not affect either aerodynamics or strength, so it would be good to install them as a minor design change. only to prove that in emergency mode the aircraft is capable of performing horizontal flight without descent, "the chief designer explained.

By mid-November 2020, a preliminary design and a preliminary design of the LMS-901 were developed, a set of working design documentation was prepared. The production of a sample for static tests, which is a frame of an airframe without landing gear, fairings, hatches and doors, is being completed.

As Vadim Demin explained, UZGA wants to make a flight model based on a statistic model, and conduct static tests on a third machine. "From the point of view of obtaining permission for the first flight, this will not cause any problems. The only thing is that at the initial stage of flight tests there will be limitations in performance. The main thing is that the plane should rise, start flying and show its childhood illnesses," he added.

According to the chief designer, the first flight prototype will be ready in the second half of 2021. Also in 2021, the gliders of the second and third copies of the aircraft will be ready, and the second flying machine will not appear until February 2022. Taking into account the use of two machines, the entire program of certification flight tests, including factory and control tests, is designed for one year. During this time, from 500 to 700 valid flights must be performed. In the basic version of the aircraft, according to the rules of visual flight, without an autopilot and with a number of other restrictions, the type certificate can be obtained by the end of 2022.

The assembly of the Baikal aircraft will be carried out at the Ulan-Ude Aviation Plant; documentation has already been sent there to assess the possibility of its manufacture. At the same time, the developers have concerns about whether the U-UAZ will be able to meet the target cost of LMS-901 production.

In accordance with the terms of reference, the price of the new An-2 should not exceed 120 million rubles in 2020 prices, the cost of a flight hour excluding leasing is 40 thousand rubles.

Polar Airlines (Yakutia), Naryan-Mar United Air Squadron (Nenets Autonomous District), Arkhangelsk 2nd United Squadron (Arkhangelsk Region), Aeroservice (Zabaikalsk Territory) and others have expressed interest in these aircraft. Within 5 years from the date of aircraft certification, Russian operators are ready to purchase at least 110 aircraft on financial lease. The purchase option includes about 50-70 aircraft in the Russian Federation and at least 50 aircraft in the CIS market. Thus, the nearest market prospect for this aircraft is estimated at 230 units.

https://bmpd.livejournal.com/4196964.html