The heart of the aircraft: aircraft engine and technical solutions capable of bringing the promising Russian VTOL aircraft to a new level, 08/10/2021.

It can be noted that with the advent of new generations of VTOL aircraft, its characteristics are getting closer to the "classic" combat aircraft of comparable weight and size characteristics. If the Yak-38 was significantly inferior to the MiG-21bis and the MiG-23ML in flight and technical characteristics (LTH), then the difference between the LTH of the Yak-141 and the MiG-29 is no longer so significant, while in some parameters the Yak-141 even won. If we talk about the American line of F-35, which contains the "classic" F-35A, VTOL F-35B and aircraft carrier version of the F-35C, then their characteristics are already quite comparable.

When they talk about the small distribution of VTOL aircraft, they forget that this technology itself is much more complicated - not every country can handle it. For example, tiltroplanes are still very little widespread, they are not even in our country, despite the rather developed aviation industry, while few doubt the effectiveness and prospects of convertiplanes. With VTOL aircraft, the situation is similar - it is quite difficult to build them without technical groundwork. In fact, only the United States has been able to do this in the XNUMXst century.

The countries of Europe are generally gradually losing their competence in the construction of combat aircraft, their development is extremely time-consuming and costly in finance. If we talk, for example, about Sweden, then in their "Grippen" there is a turbojet engine (TRD) based on the American General Electric F404 engine from the F / A-18 Hornet, that is, the Swedes themselves cannot create an engine even for a classic aircraft, what really here to talk about VTOL aircraft. Britain lost the competence to create a VTOL aircraft, abandoning the development of the next generation VTOL "Harrier" and switching to the American F-35B. France was just experimenting in this direction.

The same is with the PRC, they have a lot of things being developed and produced, but it will not work out with aircraft engines - there is a serious lag in terms of thrust and turbojet engine resource. But to create an engine for VTOL aircraft is even more difficult. It can be assumed that as soon as the engine-building industry of China solves its problems, they will be closely engaged in the topic of VTOL aircraft.

According to information from the Chinese and American media, work on the J-18 VTOL aircraft ("Jian-18", according to the NATO classification "Red Eagle") has been intensified in the PRC. The VTOL glider should be made using technologies to reduce signature, the range will be about 2 kilometers, and a radar station (radar) with an active phased antenna array (AFAR) will be installed on the J-000.

China has been trying to develop a VTOL aircraft since the 60s of the 1994th century, for which a decommissioned Harrier was even purchased from a collector in Britain. In 141, the Russian VTOL Yak-2025 was allegedly purchased for the same purposes. It is assumed that the Chinese VTOL aircraft may appear by XNUMX.

In terms of the creation of VTOL aircraft and turbojet engines for them, Russia got such a backlog from the USSR, which other countries could only envy. Despite the fact that a lot of time has passed, this reserve can and should be used.

The heart of the aircraft, on which most of its flight characteristics depend, is the turbojet engine. It is not difficult to trace the logical chain - as the specific and maximum power of the turbojet engine increased, the VTOL aircraft parameters were increasingly approaching the parameters of "classic" aircraft.

And to create a Russian VTOL aircraft, first of all, you will need to create a suitable engine for it.

Engine for VTOL aicraftThere are two ways.

The first is to create an aircraft engine for a promising VTOL aircraft based on the promising product 30 turbojet engine - the second stage engine for the Su-57, which is being worked on with long delays. It is difficult to say how realistic this is, since the characteristics of the Product 30 turbojet engine are classified, there is no information about whether this engine can be equipped with a rotary nozzle, which is significantly different from a conventional nozzle with a controlled thrust vector (SVT).

Equipping VTOL aircraft with lifting motors is not an option - this is the technology of the last century, that is, it is necessary to provide power take-off to the fan from Product 30. And whether this is possible in principle on this turbojet engine is unknown.

However, there is another possibility - at one time the engine of the Yak-141 aircraft showed outstanding characteristics, and on its basis the development of promising turbojet engines continues, which was described in the article Soviet legacy: fifth generation turbojet engine based on Product 79.

Potentially, the heart of the promising Russian VTOL aircraft can be the R579-300 turbojet engine developed by the Soyuz AMNTK.

TRD R579-300Why turbojet engine R579-300?

According to the manufacturer, this aircraft engine can be confidently attributed to the fifth generation of aircraft engines, and high performance is achieved through the use of effective design solutions, and not through the use of complex technological operations and materials, the development of which by our industry can cause delays in development and serial production promising turbojet engines.

The developer's website contains a table with the characteristics of the R579-300 turbojet engine in various versions, including options for VTOL aircraft with a maximum afterburner thrust of up to 21-23 thousand kgf.

The turbojet R579-300 has two features that make it an extremely promising solution for a promising Russian VTOL aircraft.

The first is the ability to connect a load of more than 40 MW on the turbojet shaft.

The second is an adaptive bypass ratio and an adjustable compression ratio.

The ability to connect the load on the turbojet engine shaft allows you to place a lifting fan on it, similar to how it is implemented in the F-35B. The lift fan not only eliminates the need for heavy and fuel-intensive auxiliary lift motors, but also reduces the thermal load on the runway.

In addition, with a high probability, the basis for the combat stability of combat aircraft in the XNUMXst century will be promising airborne self-defense systems, including laser systems for airborne self-defense and means of electronic warfare (EW). Increasing the power of the AFAR radar also requires a powerful source of electricity on board. This can be an electric generator on the turbojet engine shaft.

Not less, if not great opportunities will be given by an adjustable bypass ratio, which allows you to create a cold jet stream due to a large maximum bypass ratio and, accordingly, large air volumes passed through. In this case, the speed of the "cold" jet stream will be commensurate with the speed of the "hot" jet.

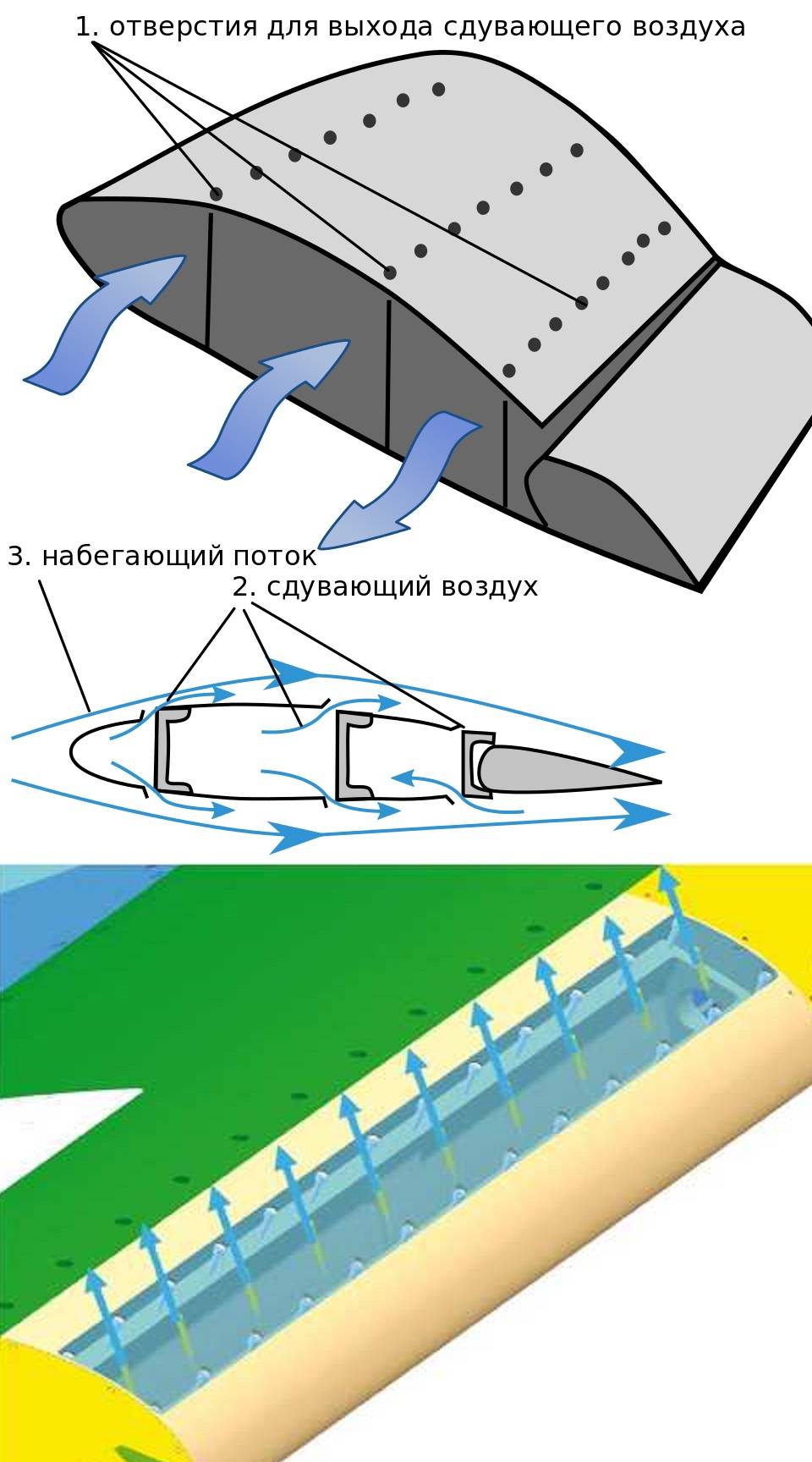

According to the developers of AMNTK Soyuz, in a promising Russian VTOL aircraft based on the R579-300 turbojet engine, vertical take-off can be realized without turning the main nozzle, by using a lifting fan and bleeding air from the external circuit, which will be ejected through small downward nozzles in the central / aft fuselage and wing tips (the latter should be used to stabilize VTOL aircraft). In this case, the temperature of the jet stream directed downward will be about 150-200 degrees Celsius, which will completely solve the problem of the destruction of runway materials during vertical takeoff (or takeoff with a short takeoff) of promising VTOL aircraft.

Potentially, an option can be considered when even a lifting fan will not be used, and vertical take-off and landing will be carried out only due to the removal of air from the "cold" circuit into nozzles located at several points of the VTOL fuselage.

But it is precisely the high temperature of the jet stream that significantly complicates the operation of VTOL aircraft both on ships and on land.

In addition to providing the possibility of "cold" vertical take-off and landing, as well as providing energy to promising laser self-defense systems, electronic warfare equipment and radar systems with AFAR, a lifting fan and an adaptive bypass ratio will make it possible to realize several more advantages in a promising VTOL aircraft.

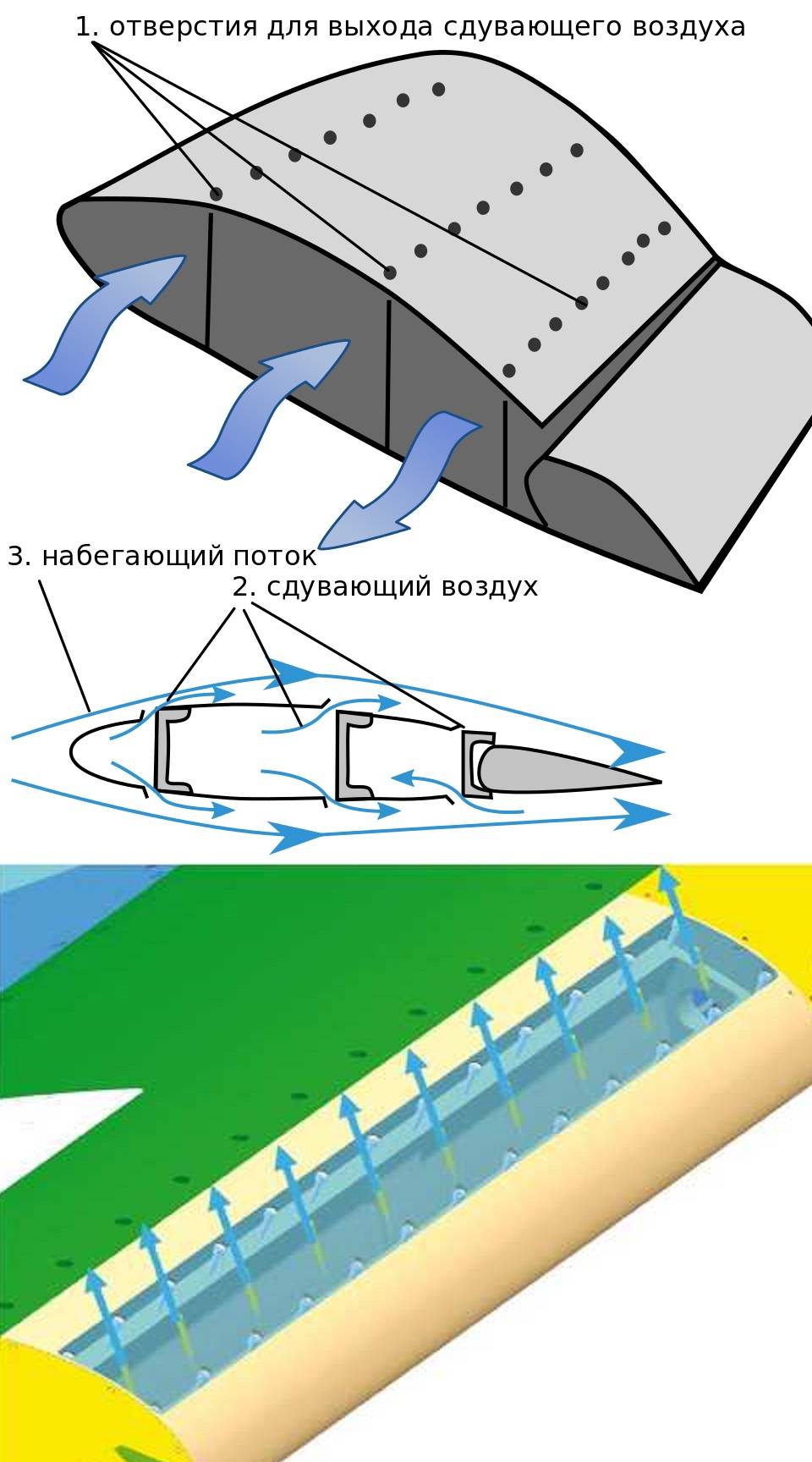

additional benefitsA large volume of cold air received from the second circuit of the turbojet engine can be used not only at the stage of vertical take-off and landing. One of the promising and effective ways to improve aerodynamics and controllability of an aircraft in the entire range of altitudes and flight speeds is boundary layer control.

Boundary layer control consists in ensuring uninterrupted flow around the wing in a wide range of angles of attack by increasing the energy of the boundary layer. The impact on the boundary layer is necessary to weaken or prevent stalling of the flow on the streamlined surface. In the USSR, blowing off the boundary layer was used by MiG-21 fighters to increase the lift of the wing during takeoff and landing - high-pressure air was supplied through a slot in the leading edge of the flaps.

In the promising VTOL aircraft with the R579-300 turbojet engine, the boundary layer control will not only improve the efficiency of the controls, but also, for example, compensate for the disadvantages of the aerodynamic efficiency of the fuselage, which may arise as a result of its optimization to reduce radar signature.

The turbojet engine's ability to create a powerful flow of cold air can be used to implement gas-dynamic control of VTOL aircraft, which, in turn, can lead to a decrease in the size of aerodynamic controls or even the abandonment of some of them and, as a consequence, to a decrease in the radar signature of a combat aircraft.

And, finally, cold air can be used to cool the turbojet engine nozzle and other structural elements, which will reduce the detection range of a promising VTOL aircraft by infrared sensors and reduce the likelihood of its being hit by missiles with infrared homing heads (IR seeker).

In principle, all this can be implemented on aircraft with horizontal takeoff and landing in the event that they have an engine with a large bypass ratio, but VTOL aircraft have another advantage, which is often considered only as a disadvantage - its lift fan.

Lifting fanBy itself, the use of a lift fan is more efficient than the use of separate jet engines, at least because of the lower fuel consumption and the cold air flow created by the lift fan, which does not destroy the runway in the same way as the incandescent jet of a jet engine directed downward does.

In addition, the implementation of the lifting fan will require the development of the technology of taking high power from the turbojet engine shaft. A side effect of this technology will be the possibility of placing on the turbojet engine shaft, in addition to the lifting fan itself, also an electric energy generator, which is vital to provide power to the onboard laser self-defense systems, electronic warfare equipment and radar with AFAR, as already mentioned above.

The presence of powerful sources of electricity and air supply on board the VTOL aircraft will completely abandon unreliable and fire hazardous hydraulic drives in favor of electric and pneumatic drives.

Along with fuel, air is the most important component that allows the turbojet engine to realize all its characteristics. There are situations when the amount of air supplied to the turbojet engine installed on board the aircraft becomes insufficient. This problem can arise when the aircraft is operated at high-altitude airfields, at high flight altitudes, or during intensive maneuvering.

In this situation, a promising VTOL aircraft can use a lift fan to pump additional air volumes to the engine, with the upper flaps open and the lower flaps closed. In this case, the air flow through special channels will enter the turbojet engine, allowing it to operate at maximum power.

For example, somewhere at a high-altitude airfield to take off a "classic" combat aircraft with a full combat load, a runway with a length of one and a half kilometers will be required, while a VTOL aircraft, due to the provision of a turbojet engine with additional air volumes, will carry out a "horizontal" take-off from a runway with a length of 300-500 meters.

ConclusionsThe growth of the specific and maximum, afterburner and non-afterburning power of the turbojet engine largely eliminates the differences between the "classic" aircraft and VTOL aircraft.

It can be assumed that the characteristics of promising "classic" combat aircraft and VTOL aircraft will differ within 10-15%. For example, a VTOL aircraft will have 1–2 tons less combat load, which is tolerable if a "classic" aircraft has 8 tons, and a VTOL aircraft of 6-7 tons, all the same, the aircraft simply does not have enough suspension points, especially intra-fuselage ones, so that hang weapons on such a mass. Or the ferry range of a "classic" aircraft will be 200-300 kilometers longer than that of a VTOL aircraft, which is not critical when it is about three to four thousand kilometers.

At the same time, VTOL aircraft will have advantages that cannot be realized on "classic" combat aircraft.

Under the revolutionary development of space reconnaissance assets и long-range precision weapons, including hypersonic, to ensure the survivability of combat aircraft in the event of a sudden enemy strike, only the possibility of dispersing combat aircraft over small camouflaged airfields can help.

The combination of VTOL aircraft and developed services for the operational deployment of mobile airfields will make it possible to create a fleet of combat aircraft that is most resistant to deep attacks by the enemy.

And, of course, VTOL aircraft will find their niche in the Russian naval navy (Navy).

AUTHOR: Andrey Mitrofanov for en.topwar.ru

Isos

Isos