Russia creates unique aviation technology, by Alexey Anpilogov for VZGLYAD. April 14, 2022.

Against the background of constant sanctions against the most important industrial sectors of Russia, our country is introducing its own latest technologies. This time we are talking about a new way of producing a key part of modern aircraft engines. What exactly is new and why is it critical for the entire aviation industry?

The United Engine Corporation Rostec announced that its enterprises have mastered a unique technology for manufacturing aircraft engine blades. There are only six countries in the world that have complete technologies for the design and manufacture of blades - and now Russia has consolidated its leadership in this industry. To explain the exceptional importance of this event, we will have to delve into the technical part of the issue.

A modern turbojet or turbofan engine cannot be imagined without many blades. Climbing up the gangway of a passenger plane, we see their "palisade" in the frontal projection of the aircraft engine - but this is only the first row of blades. This part of the engine that is open to the naked eye is called the compressor, and it compresses the incoming air flow during the operation of the aircraft engine.

Compressor blades direct the oncoming flow, allowing it to compress as smoothly as possible. This is necessary so that there are no unnecessary and destructive pressure surges in the compressor inlet channel, and the engine itself provides minimal drag. It is for these purposes that the blades are given a complex, curved shape that maximally repeats the direction of the oncoming flow, which is forced to pass inside the aircraft engine along a complex, contracting spiral.

To ensure that this spiral and, as a result, the air path in the compressor is as long as possible, and the pressure increase is gradual, the compressor is made multi-stage, lining up the blades in a dozen successive rows. Therefore, if we cut a turbojet or turbofan engine, inside it we will see basically two main blocks - a compressor and a turbine, between which there is a compact combustion chamber.

In the combustion chamber, compressed and heated air is mixed with aviation kerosene - and the fuel is burned. The air heats up sharply, after which it enters the second bladed unit - the turbine. At the turbine, part of the energy of the jet stream is taken away, also with blades. This energy allows the compressor to rotate, providing compression of new portions of air.

Most of the energy in the heated air escapes the engine, creating jet thrust that propels the aircraft forward. The turbine of an aircraft engine is also made multi-stage, and the blades in it, again, have a complex curvilinear shape in order to ensure the most smooth expansion of the jet stream.

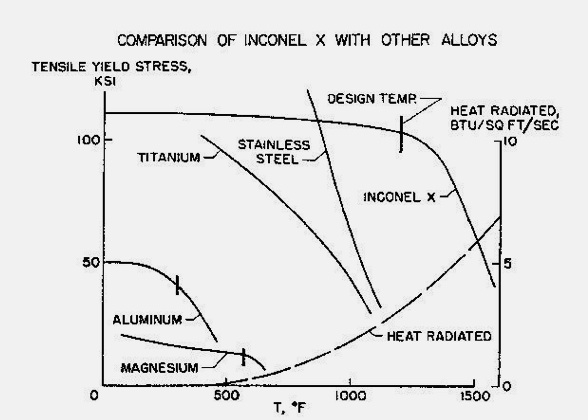

During their operation, the blades of the compressor and turbine experience strong and multidirectional mechanical effects: centrifugal forces, resistance to the oncoming air flow. In addition, the turbine blades operate at high temperatures - the jet stream at the first stages of the turbine has a temperature of more than 1000 ºС. Therefore, for the manufacture of blades, a reliable, lightweight and heat-resistant material is needed.

As a result, the blade of a gas turbine engine is one of the most complex and science-intensive in the design and manufacture of aircraft engine parts. In its production, rare metals and unique alloys are used, as well as composite materials that guarantee the lightness and strength of the workpiece.

The aluminum that makes up the body of the aircraft is of little use for blades, and heat-resistant steel is still too heavy. The ideal material for the blade is titanium - a light, durable and heat-resistant metal. Even a composite can be made from titanium: for this, a two-phase version of titanium can be created in an ingot, where one of the phases will be responsible for the strength and hardness of the outer, surface layer of the blade, and the inner part, with another phase, will provide the overall flexibility of the part.

However, titanium processing has its own peculiarities. Since the blade has a complex curvilinear shape, it is very expensive to manufacture it by machining. After all, if it is machined from a solid workpiece, then the consumption of material and tools will simply be unacceptable. It is not so easy to use welding - titanium is a capricious material in welding operations, and any welding seam in such a critical part as a blade will be a weak point.

As a result, stamping has become the most economical and high-quality technology for manufacturing compressor and aircraft engine turbine blades in the world, when the blade profile is obtained by plastic deformation of the original workpiece. In this embodiment, machining is minimal and serves only to give the finished product precise contours, mainly created as a result of stamping. There are no welds either - the blade is a monolith obtained from a single workpiece.

Stamping of titanium products is an extremely difficult technological operation. Many titanium alloys have a very narrow "temperature window" for efficient stamping. Heated the part above the norm - the properties of the titanium composite will be lost, submitted it to the press too cold - stamping will introduce mechanical damage and ruptures into the metal structure. In addition, the selected technology of controlled bending of the billet into the finished blade makes it possible to make stamping as "softly" as possible, leaving all the advantages of a two-phase titanium composite in the finished blade.

Therefore, the development in Russia of the technology of high-precision forging of titanium blades is not just a small technological “improvement”, but also a whole layer of scientific, design and production research, which made it possible to create an innovative technical process for the most critical and important part of any aircraft engine.

The described technologies will now be used by the Rostec United Engine Corporation in the development and production of the PD-8 civil aircraft engine line for the Sukhoi Superjet SSJ-NEW aircraft, in the PD-14 engine for the MS-21 medium-haul airliner, and in a new development - the PD- 35 for advanced wide-body long-haul aircraft.

Thus, existing and prospective Russian aircraft will be able to receive a complete and diverse line of domestic aircraft engines, which will be either on a par with or even higher than the world's best models in terms of their technological level. After all, the use of a titanium-based composite alloy is an absolute step forward in the design of an aircraft engine. It provides a lighter product weight, longer blade life and, as a result, longer overhaul periods and reduced maintenance costs.

In addition, technological sanctions, which are now used to scare the Russian aviation industry, are becoming useless. Again and again, “Russia does it itself”, showing that a scientific and industrial school lives and develops in our country, working at the very forefront of world scientific and technical thought.

https://vz.ru/society/2022/4/14/1153500.html

Rodion_Romanovic

Rodion_Romanovic