Big_Gazza wrote:

Sure, we could assemble spacecraft in space, but that is using pre-fabricated modules built planet-side. Actually manufacturing in space is several levels of magnitude harder. How difficult and expensive and time-consuming is it to build a relatively simple ferry for humans/cargo (eg Soyuz/Shenzhen/Dragon) or station modules (eg the MLM fiasco..)? Now consider buildingn them in orbit.... Try building a Soyuz in a workshop that is a hard vacuum using robots and workers in EVA suits, and see how the cost & schedule soars into the exosphere.... Now try manufacturing the sub-components as well....

We don't seem to have any problems here on Earth in mass-producing RAM chips or microprocessors, so why build them in space? What is to be gained? materials fabrication experiments have been conducted for decades, first in Salyut 6/7/Mir and now in ISS, and we STILL haven't figured out any cost effective way to manufacture useful quantities of "ultra-pure" semiconductors.

initial investment is prohibitive??? Try absurd and utterly unrealistic.

I dont want to piss on people parades, but somewhere along the line we need to be realistic aboit what it is possible to achieve, and why we should want to do it. I'm all for robotic exploration of the solar system, but putting meat-sacks in space craft isn't particularly productive or effective. We should be concentrating on robotic technologies and lowering the cost of expensive robotic spacecraft by serial production of standardised spacecraft bus designs and kitting them as needed for specific missions. The current approach (completely new design each mission), even when HIGHLY successful (like what NASA & ESA does) is at a premium cost and they don't reuse the proven solutions for new missions because the manufacturers are private aerospace entities that are in competition and are driven by profit. NASA proved the 2x MER rovers, but did they then build another 3-4 and launch them to other areas? No, they threw away the engineering legacy and went for an entirely new and FAR more expensive design, and only launched one. While the Soviets could never hold a candle to NASAs sophistication, they leveraged their tech with each misison and built on what had succeeded before (or fixed what failed...). The Veneras were essentially a production line, with evolutionary improvements in cameras and soil samplers, and were a huge success.

Forget meat-sacks in space and build robots, lots of them. Build a number of standard designs and start to mass produce. Send them everywhere, and if they fail, just send another one (and tweak the mission package accordingly).

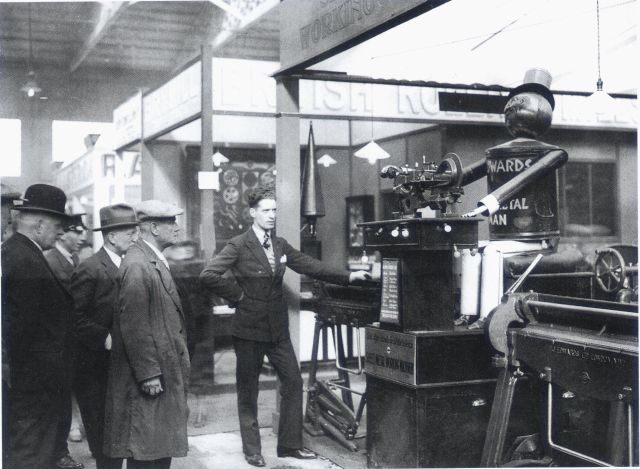

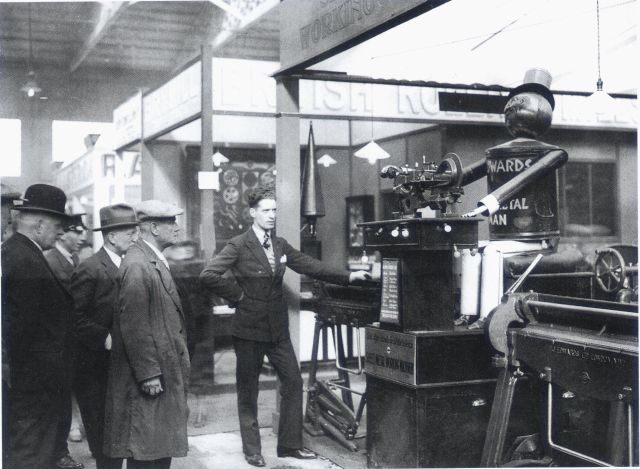

Your view about a space industry is pretty much like the above picture, showing a robotic machining centre, operated by a humanoid robot.

You can say that " it is not possible to make robot controlled machine, because it is so complicated to make humanoid robots ! " : D

You can't make space industry without humans.

Simply not possible. Humans can make decisions that lead to valuable results, the robots are nothing else just remote operate machines, with limited scope of usability.

Are you aware what kind of challenges are in the semi industry?

It is not about to make pure silicon - that is easy.

It is about to make a clean environment, and generate hard vacuum in the machines .

Two third of the investment of a modern semi fab is to be able to generate clean air, big part of the leftover third is for cleaning .Small potion is required for the actual manufacturing.

So, per definition a space bound semi fab cost fraction compared to the earth one.

Same to make soyuz in the space.

Why you want to do that?

A space capsule is a pressure chamber, that can be manufactured by blowing , spiral welding , or centrifugal casting.

All of them is easy and cheap in the space.

But if you don't want to go that far, the easiest and most demand stuff is the fuel.

And actually you can use as fuel (reaction mass) anything.

PapaDragon

PapaDragon